Turn-Key Coil Replacement

With over 25 years of experience, Nooter/Eriksen has the knowledge and experience to do more than simply replace aging HRSG coils. Whether it is addressing coil failure root causes, such as FAC(Flow Accelerated Corrosion) and Cyclic Fatigue, or it is improving operational conditions such as fluid and gas side pressure drop, Nooter/Eriksen has the experience needed to transform many “replace in-kind” projects and offer the best combination of future reliability, performance and overall value.

Based on our extensive experience and industry leading engineering approach, Nooter/Eriksen can offer innovative construction solutions that will improve project timetables and reduce overall job complexity in order to help customers minimize costly downtime.

As an equipment supplier with an experienced installation team Nooter/Eriksen can provide the component fabrication, field installation and management of various sub-contracts for the project, with the aim of providing a seamless experience for our customer with a single point of contact, all without sacrificing quality or value.

Four different types of Coil Replacements

Shop Modular

Each module is ready to lift and

set in place with heat transfer

coils shop installed in the casing.

Structural steel and gas baffles

are fully attached. No external

lifting devices are required. This

construction is utilized with single

wide units.

C-Frame

Each module is ready to lift and set in place with heat transfer coils shop installed in the casing. Structural steel and gas baffles are fully attached. No external lifting devices are required. This construction is utilized with double wide units.

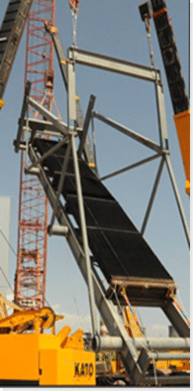

Large Modular Design

Can be adapted to any size HRSG by varying width and quantity of modules. Can be shipped anywhere. Use of primary/secondary panels minimizes linear feet of casing weld. Half as many column lines as C-frame or Shop Modular. External lifting devices are required.

Small Modular

Similar to the Large Modular Design however this design utilizes small , shop fabricated heat transfer modules designed to take into account logistic restrictions and/or job site crane limitations.