Concentrated Solar Power Receivers

Nooter/Eriksen is designing and supplying state of the art molten salt receivers (MSR) to be integrated in a concentrated solar power (CSP) tower project. The current Nooter/Eriksen design is capable to heat the molten salt up to 560°C (1040°F) and withstand the specified heat flux from the heliostat field. Nooter/Eriksen partnered with SolarReserve through a 9 year cooperation resulting in the supply of the receiver at Crescent Dunes. Nooter/Eriksen has now taken the lead role with the receiver one hundred percent designed and supplied by Nooter/Eriksen. Many improvements have been incorporated in the receiver design based on the operating experience of Crescent Dunes in Tonopah, Nevada.

Crescent Dunes was the first concentrated solar power (CSP) plant with a central receiver tower and advanced molten salt energy storage technology. The Project, located near Tonopah, NV about 190 miles (310 km) northwest of Las Vegas, has an installed output capacity of 110 megawatt (MWe) and 1.1 gigawatt-hours of energy storage.

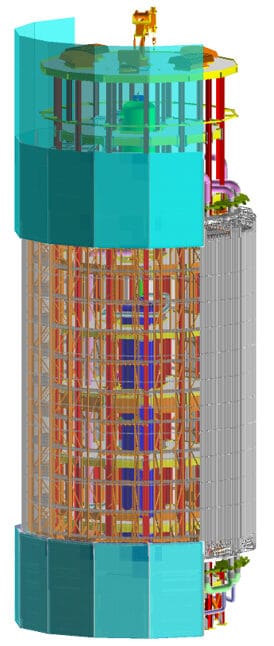

Nooter/Eriksen Molten Salt Receiver Assembly

Nooter/Eriksen has developed the technology to offer our Molten Salt Receiver (MSR), capable of heating Solar Salt (60 mol% NaNO3-40 mol% KNO3) to 565°C. The receiver leverages the experience we gained constructing and operating the 565 MWth MSR at the Crescent Dunes Solar Energy Project. The Crescent Dunes receiver validated the performance that was expected for thermal efficiency, pressure drop, and tube temperatures.