Lowest Installed Cost: Field construction solutions that cater to project specific needs

Nooter/Eriksen will offer an evaluated solution of in-land transportation restrictions and local field construction challenges to provide an optimal solution for your jobsite. Design details are developed to minimize field construction hours and all the components are maximized in size within shipping limitations. Options are available to further maximize shop fabrication. Components can be designed to address jobsite space or crane limitations. All consideration is given to minimize the total installed cost to provide the best value to our customers.

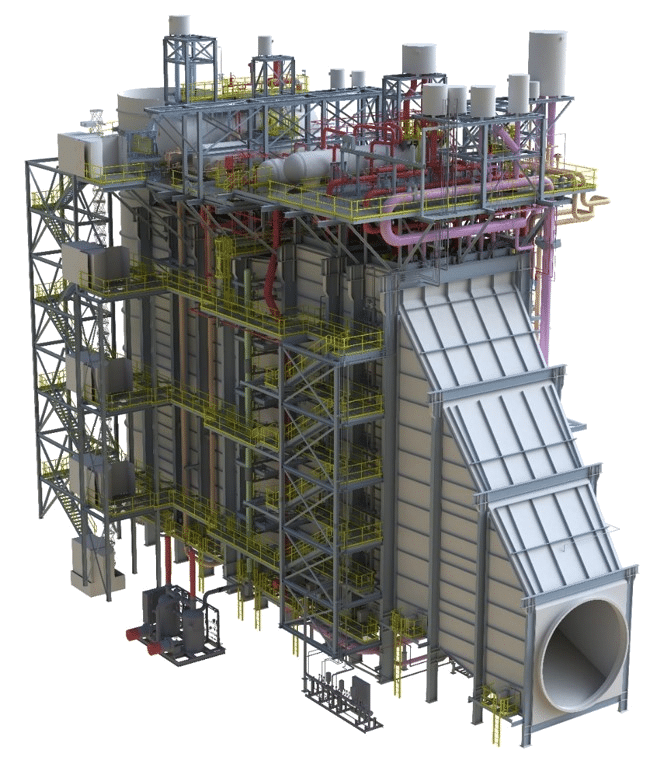

Large Modular Construction

Casing panels shipped in full length sections with structural steel columns attached.

- Bolted/Welded or 100% Bolted moment connections.

- All external stiffeners shop installed.

- No internal temporary steel with modules.

- Sidewall gas baffles shop installed

- Casing erected in 3-4 weeks.

Coil bundles shipped in large modules

- Average of 2-3 modules set a day. 5 modules have been set in a day.

- Module installation order is flexible

Modules are shipped with roof casings, piping penetrations, upper gas baffles, packing glands all shop installed.

- No large bore piping welding inside casing

- No center gas baffles required between Modules

C-Frame Module Construction

Each module ready to lift into place upon arrival. Modules include:

- Heat transfer coil.

- Roof, floor and sidewall casing.

- Roof, floor and sidewall structural members.

- All large and small bore nozzle penetrations.

- All gas baffles shop installed.

Innovative field seam design:

- Able to remove temporary steel through field seam in one piece.

- Field seams are externally packed.

- Enables use of a JLG and no scaffolding on the inside.

Other Benefits:

- No external lifting device needed.

- Easy to fit and bolt splice.

Shop Modular Construction

HRSGs designed behind CTs ranging in size from 20-90MW. Modules include:

- Each module will contain one or more heat transfer coils with the casing and structural steel fully attached.

- All internal fabrication completed at shop. No internal large bore welding or baffling required in the field.

- All nozzles terminate outside the casing, with the packing glands and expansion bellows shop installed

Innovative field seam design:

- Field seams are externally packed.

- Enables use of a JLG and no scaffolding on the inside.

Other Benefits:

- No external lifting device needed.

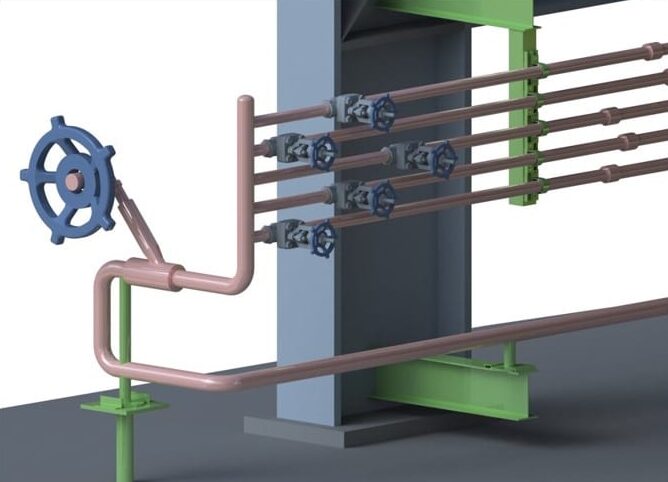

Constructability Innovations -Valves, Instruments & Piping

Shop Welded in Valves

N/E can provide the large bore valves and economizer drain valves shop-welded, saving both time and money.

- Welds are done in a more controlled shop environment.

- Reduces valve handling, storage, staging, welding, PWHT and NDE at site.

- Pipe spools without valves are still shipped from shop once ready, allowing Field Erector to start with piping as usual.

- The assembled shop-welded valve spools arrive shortly thereafter, ready for installation, resulting in an overall field erection schedule savings.

Small Bore Pipe Spools

N/E can provide the small bore piping spooled with shop welded in valves for approximately 75% of the small bore pipe welds. The spools will fit in standard shipping containers or on a standard truck.

Shop Welding of Pipe Supports

N/E can supply large bore pipe support stanchions and stanchion base plates welded to the pipe in the shop

- In addition to savings on field welds, the savings for PWHT and NDE can be significant (particularly for alloy pipe materials)

- Approximately 90% of the pipe support welds to the piping can be welded in the shop

Reduced Risers

N/E can design for fewer risers:

- Reduction in manhours needed to field weld risers.

- Cleaner layout on top of the HRSG.

- Fewer nozzle penetrations, reducing the risk for hot spots.

Constructability Innovations – Platforms & Stairtower

Bolted Platforms

N/E can provide an option for bolted platforms. Traditionally about 50% of the connections would be bolted and 50% welded. Under this option, nearly 100% would be bolted.

Stackable Stairtower

Installation in 4-5 days vs. typical 2-3 weeks

Standard

- Shipped in approx. 150 pcs

- Bolted connections

Stackable Option

- Shop assembled cubes (~10 cubes + handrails)

- Sized to fit on truck for delivery