HRSG INNOVATION

Research and development is a key part of Nooter/Eriksen’s on-going product improvement. An entire department of engineers is dedicated full-time to exploring areas for continuous improvement.

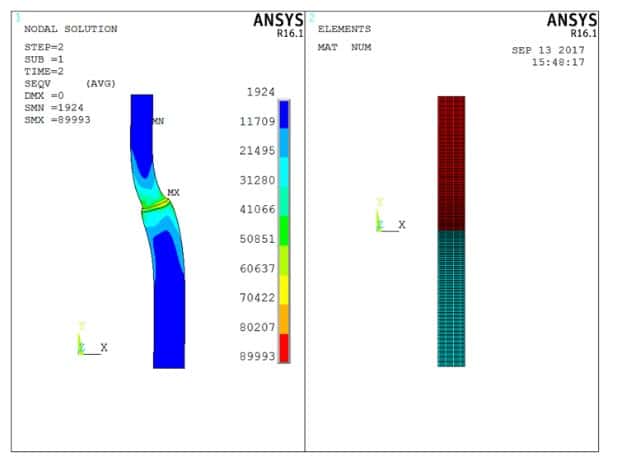

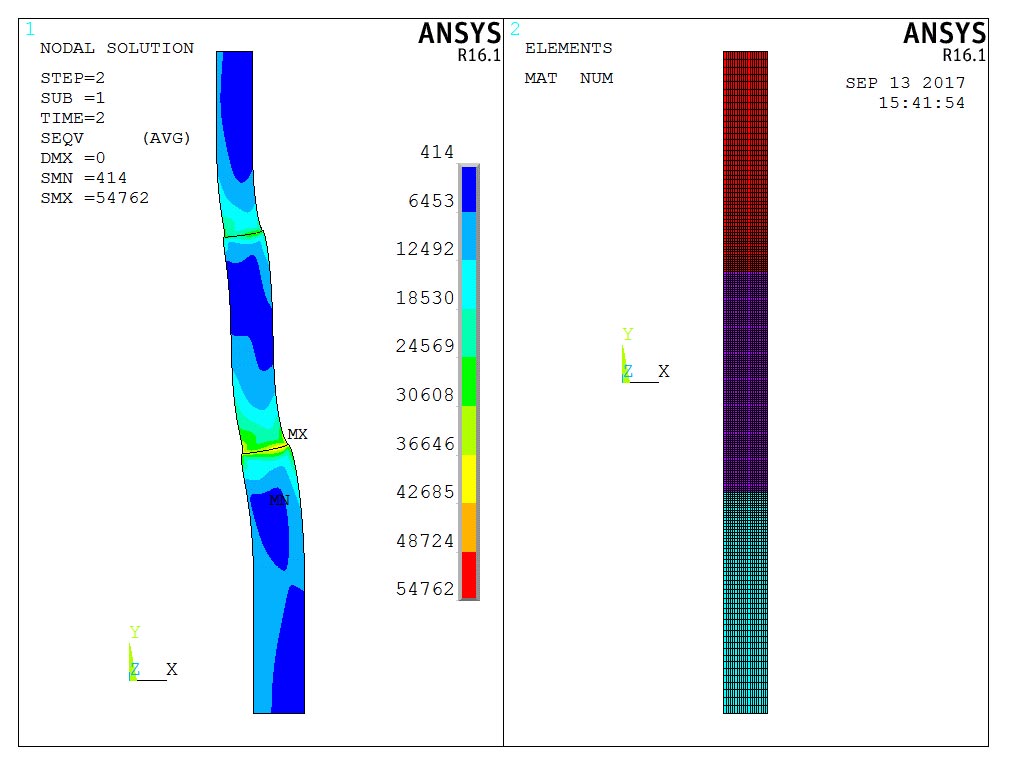

Nooter/Eriksen provides innovative solutions for common industry issues. We have patented systems which replace recirculation pumps to increase inlet water temperature to prevent cold end corrosion with an external heat exchanger. We have high quality large bore casing drain penetrations to ease installation and prevent leakage. We have a trouble-free design for the blowdown piping and blowdown tank. Additionally, Nooter/Eriksen can provide the heat balance solution to optimize the performance for the unique needs of your plant. We also have extensive capabilities to support customer requests to perform structural Finite Element Analysis (FEA) for critical components of the heat recovery boiler operating in cycling modes.

Nooter/Eriksen supplied HRSGs are:

- Design Driven vs. Manufacturing Driven

- Responsive to Customer Feedback and Industry Concerns

- Continuously improved through the R&D process

Nooter/Eriksen devotes extensive resources to research and design – both in the field and in our own testing facilities, where we validate heat transfer correlations for a multitude of different fin configurations.

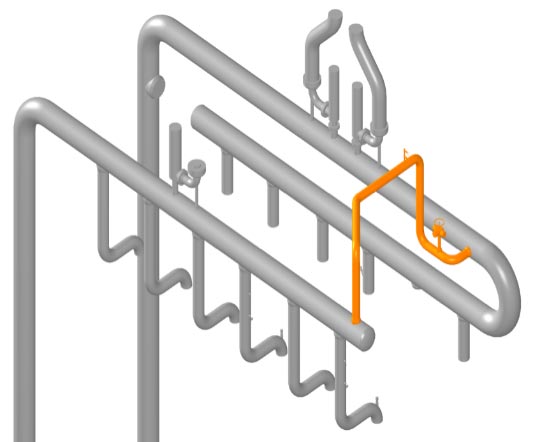

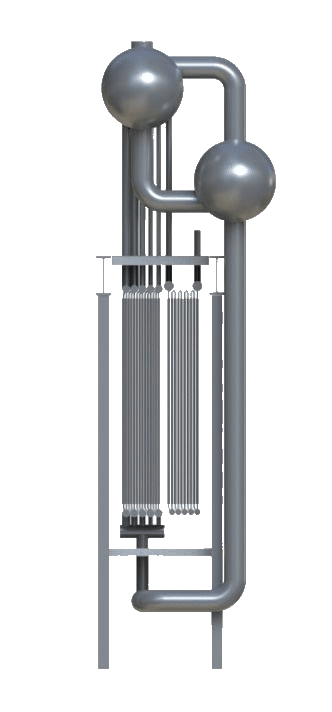

To supply reliable highly efficient equipment, Nooter/Eriksen has dedicated extensive time and effort in developing a multitude of design details which have been incorporated in Nooter/Eriksen HRSGs. You can investigate some of those through the interactive model below. This section highlights a few of the numerous design improvements you will benefit from by selecting a Nooter/Eriksen HRSG.

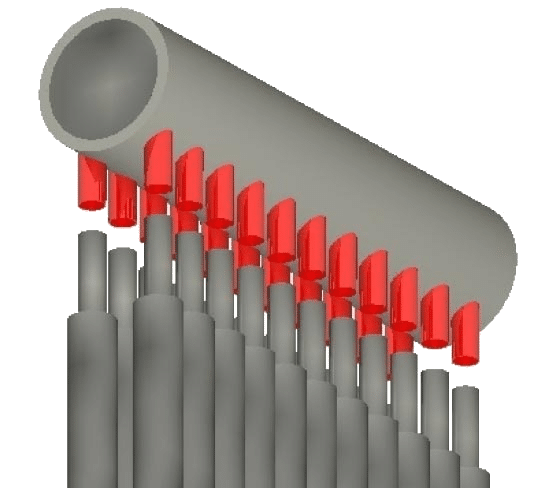

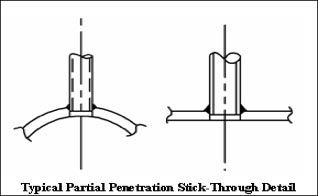

1. TUBE TO HEADER ATTACHMENT

Nooter/Eriksen pays particular attention to the areas of the HRSG subject to the highest fatigue stress, one of the primary areas being the HP superheater and the reheater sections due to large through wall temperature gradients during transient operation. Nearly all modern combined cycle plants require HRSGs designed for frequent cycling which increases fatigue damage on the HRSG. It is critical that the HP superheaters and reheaters are properly designed to accommodate the intended operation.

Nooter/Eriksen HP superheaters and reheaters are designed to accommodate the fatigue damage resulting from cyclic operation and creep damage from sustained operation at elevated stresses and high temperatures by:

- Designing with hillside tube to upper header arrangement to avoid tube bends

-

- Reduces header thicknesses for improved through wall temperature gradients

- Allows inspection before attaching tube for greater reliability

Partial Penetration Stick-Through Detail

Stick-Through tube to header connections are used in colder coils (HP Evaporators and all downstream coils) where temperature gradients from transient operation are less significant allowing for easier fabrication.

2. HIGH TEMPERATURE DESIGN

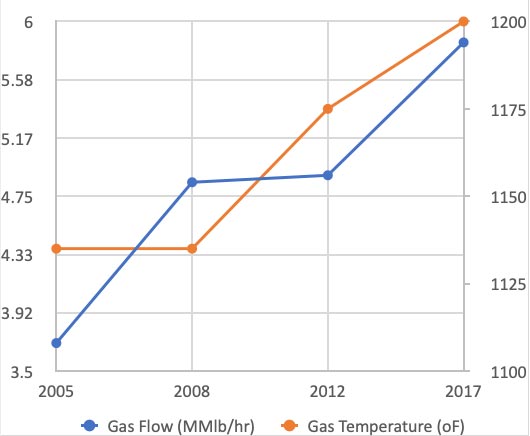

New gas turbines are continuously increasing their efficiency with the consequence that exhaust gas temperature has increased. This allows the HRSG to produce higher pressure and temperature steam to the benefit of the steam turbine. This requires material capable of withstanding creep and oxidation to provide reliable performance over the life of the equipment.

ASTM A213 Grade T91 for tubing and ASTM A-335 Grade P91 for headers and piping was introduced in fossil fuel applications in the mid-1980s. The improved strength of Grade 91 allowed for thinner sections and better oxidation resistance. Nooter/Eriksen has provided over 250 HRSGs with 91 Materials since the late 1990s.

We are close to or exceeding the maximum recommended service temperatures of 91 materials. N/E is exploring the use of other CSEF materials which are being developed to fill the gap between Grade 91 and stainless steel. N/E uses austenitic stainless steel when the cycle temperature exceeds the limits of ferritic steel.

To limit the number of dissimilar metal welds and make them accessible for inspection during operation, Nooter/Eriksen offered solution is to provide stainless steel tubes and headers, installing the Inconel transition outside the HRSG casing.

3. COIL AND PIPING FLEXIBILITY

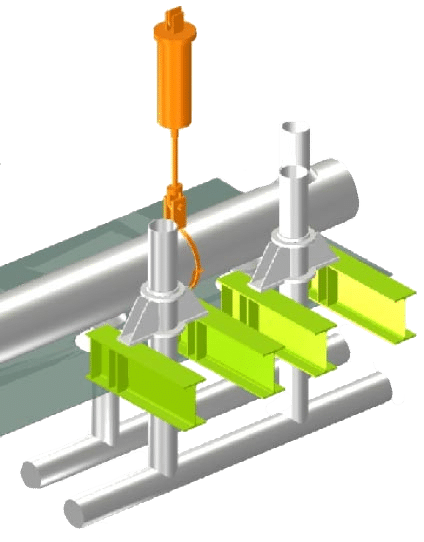

Nooter/Eriksen superheater and reheater coils are designed with flexibility in mind. When required to accommodate differential operating temperatures within the coil and cyclic operation, Nooter/Eriksen utilizes spring-can hangers for coil support.

The benefits are:

- Lower internal thermal stresses

- Lower tube bending at upper headers

- No lower header vertical movement restrictions

- No row-to-row expansion restrictions

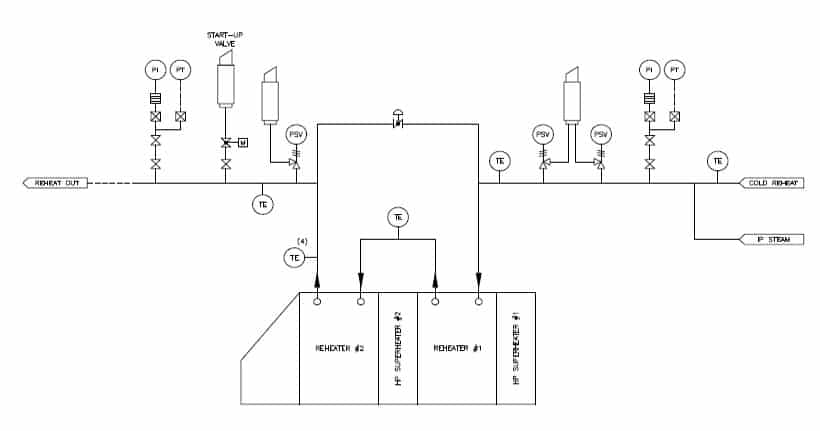

4. REHEATER BYPASS

Nooter/Eriksen recommends the use of a steam bypass attemperator for reheat steam temperature control in lieu of spraywater attemperation when design conditions allow. The reheat bypass attemperator utilizes cold reheat steam to control the hot reheat outlet temperature using the arrangement shown in the P&ID below.

Steam bypass attemperation offers a number of benefits when compared to spraywater desuperheating:

- Increased HP steam production in cases that require reheat attemperation.

- Increased reliability of the HRSG as a result of a less complicated control system and the elimination of the risk for catastrophic failure of a pressure part due to improper use of liquid spraywater or failure of the spraywater attemperator.

- Improved RH steam purity

- The steam bypass attemperation system requires less maintenance than a spraywater desuperheating system.

- The steam bypass attemperator is more cost effective than the spraywater type attemperator.

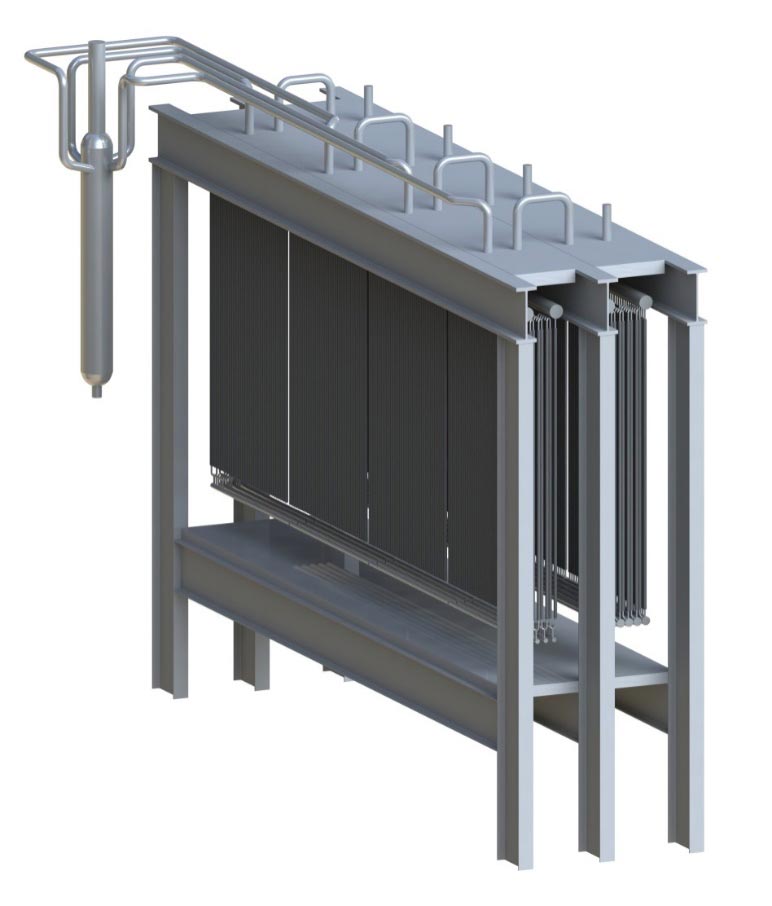

5. ECONOMIZER DESIGN

The economizer experiences remarkable differential thermal expansion.

Nooter/Eriksen standard design utilizes return bends between tube rows for superior flexibility.

Our design does not restrict lower header vertical movement and we prohibit tube bends at feedwater inlet headers to further accommodate temperature differences within the first tube row.

The Nooter/Eriksen economizer design has superior flow distribution as all circuits are hydrodynamically identical. Our economizer design accommodates steaming in the hottest tubes using an upflow double circuit (and thus double of the cross section) configuration allowing steam bubbles to vent through the outlet header.

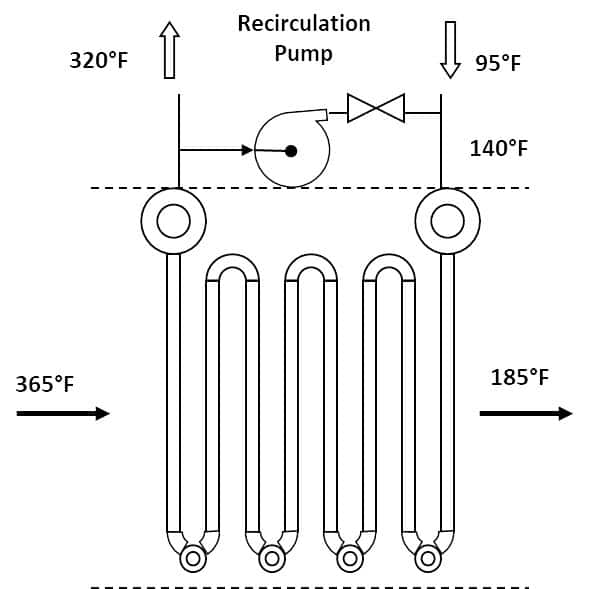

6. COLD END CORROSION

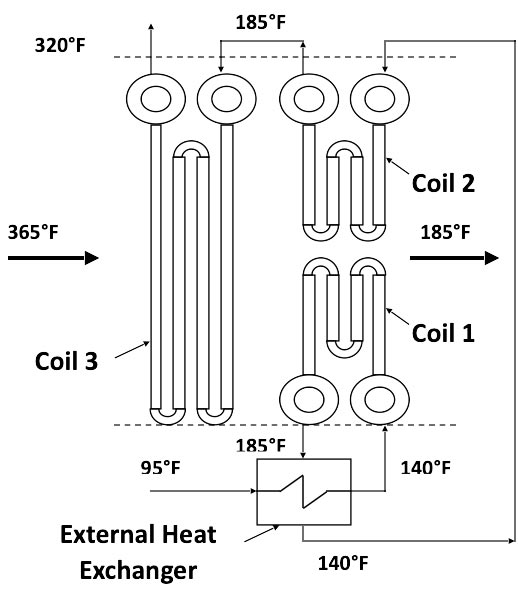

Standard design to prevent acid condensation on the preheater surfaces is to provide a recirculation pump to raise the feedwater temperature to the design value.

This solution has a parasitic power loss for the recirculating pump motor.

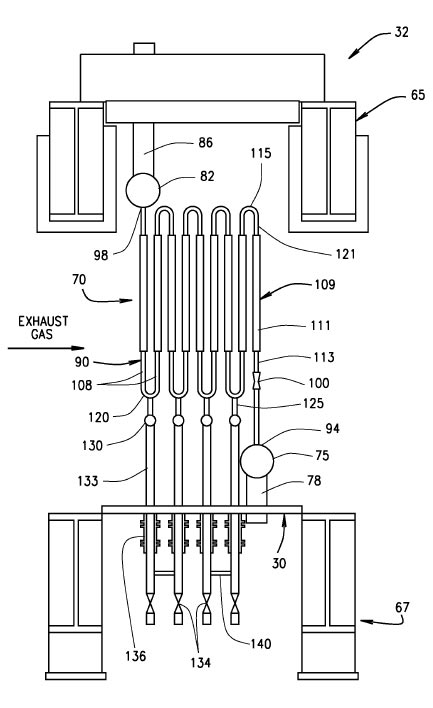

Nooter/Eriksen has addressed this problem with a proprietary design by installing an External Heat Exchanger (U.S. Patent No. 6,508,206)

The advantages of the Nooter/Eriksen patented system are:

- Reduced initial cost – heat exchanger is less expensive than recirculation pump

- Reduced operating cost – heat exchanger does not require power

- Reduced maintenance costs – no rotating equipment

- No external source of heat

- No exotic materials

- Process requirements are not affected

For projects with non-deaerated condensate, the standard design is to provide a preheater with duplex (UNS S31803/S32205) tube material.

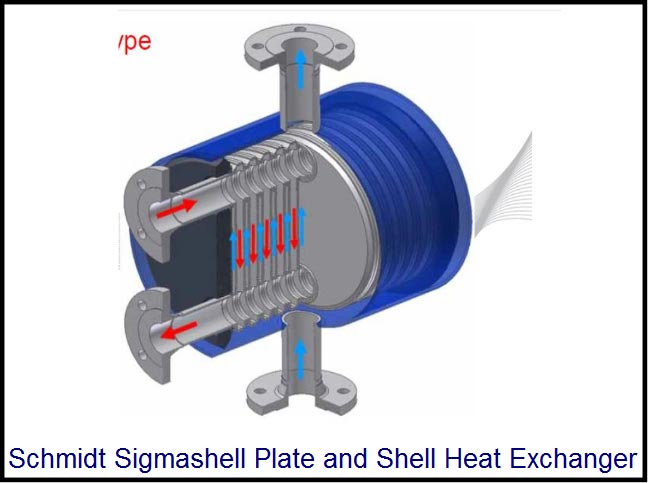

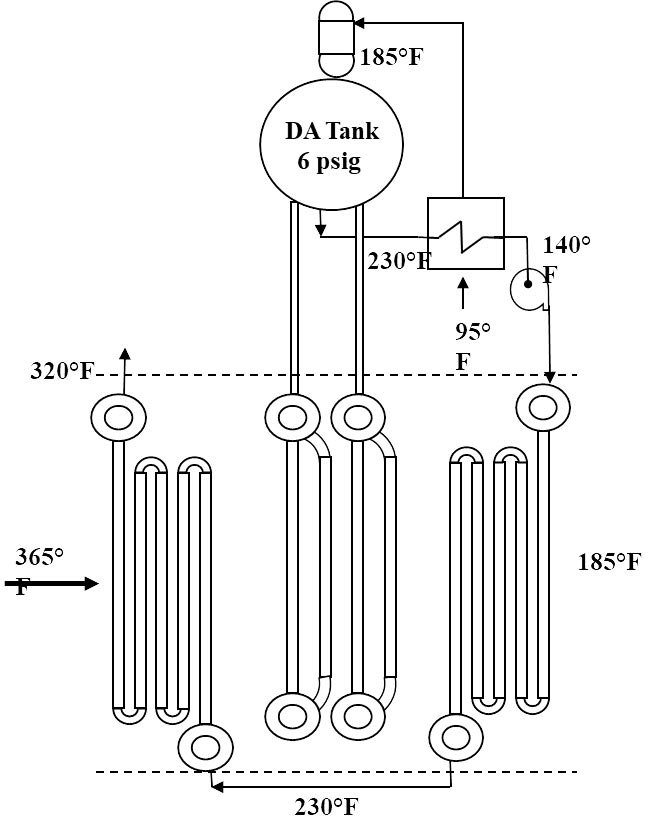

NE has developed a proprietary alternative design called a High Efficiency Feedwater Heater (U.S. Patent Pub. No. US 2012/0037097 A1)

High Efficiency Feedwater Heater

The advantages of the NE patented solution are:

- Increased low pressure steam production – no LP steam for deaeration

- Reduced initial cost – stainless steel tubes are replaced by carbon steel

- Reduced operating cost – heat exchanger does not require power

- Reduced maintenance costs – no rotating equipment

- No external source of heat

- No exotic materials

- Process requirements are not affected

7. MULTI DRUM DESIGN (U.S. Patent No. 9,921,001)

Especially when the HP steam pressure is very high and the HRSG is designed for frequent cycling and high ramp rates, the thickness of the HP steam drum is a limiting factor for the start up transient that the HRSG can withstand. An alternative to a once through design, which requires expensive water treatment and a sophisticated control system, is to utilize the Nooter/Eriksen patented solution of multi drum design.

The advantages are:

- Minimizes drum through wall temperature gradients

- Control philosophy follows traditional combined cycle facilities

- Smaller drums with same retention as conventional single drum

- Conventional natural circulation

- Conventional water treatment

- Process features and limits are not affected

8. SUPERCRITICAL EVAPORATOR (U.S. Patent No. 10,634,339)

For HRSG designs with supercritical steam parameters, a once through steam generator is required for the high pressure evaporator. NE patented design utilizes a horizontal exhaust gas path with vertical serpentine tube arrangement.