Enhanced Oil Recovery Steam Generators (EORs)

Nooter/Eriksen designs and supplies Enhanced Oil Recovery Steam Generator (EORs) which are used in oil fields to increase the amount of oil that can be extracted. Saturated steam is injected into the oil field to reduce the viscosity of the oil and improve the percentage recovery. Nooter/Eriksen supplies EORs that are installed at the exhaust of a combustion turbine; thereby recovering exhaust gas energy and, at the same time, providing steam for the oil fields.

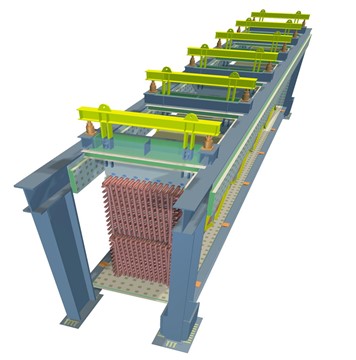

An EOR is a ‘once through’ HRSG with no superheating. Heat transfer tubes are arranged horizontally with water-cooled supports in high exhaust gas temperature area. Steam produced ranges from 60-80% quality at pressures from 60-150 barg (880–2200 psig). The EOR HRSG can be designed with or without duct firing depending on the steam demand.

Water quality requirements are much lower than in a typical HRSG because there are no downstream requirements that a steam turbine requires and many of the solids are carried out with water phase in the saturated steam. Additionally, these units are designed to be mechanically cleaned on the tube side.

Nooter/Eriksen is the worldwide leader supplier of EOR HRSG installed downstream of a gas turbine. Nooter/Eriksen is capable to design both bottom and top supported units, the second solution being more appropriate for retrofitting behind larger gas turbines.

Top supported modules

Nooter/Eriksen has been supplying EORs for over twenty years and has experience with all turbine sizes. Currently we have a license agreement with TIW Western (TIWW) that allows them to supply EORs into the Canadian market.

TIWW has also licensed NE the Technology For direct fired Enhanced Oil Recovery Applications. TIWW is the leader supplier for Units from 25MMBTU/hr up to 590MMBTU/hr with 80% quality steam. Design pressure goes from 725 psig to 2,500 psig, from single circuit to 8 pass multi-circuit design, single or multi-fuel units.