The Advantages and Applications of Automated Welding Technology

The Advantages and Applications of Automated Welding Technology

Welding has been an essential component in mechanical construction since its inception. This process of joining metals by applying heat and pressure has seen significant advancements over the years, resulting in improved welding techniques and equipment. One innovation with the potential to revolutionize the construction industry is automated welding technology.

This blog post will explore the advantages and applications of automated welding technology and how it is transforming mechanical construction processes.

Advantages of Automated Welding Technology

Automated welding technology offers numerous benefits that make it a game-changer for the mechanical construction industry.

See: The Mechanical Construction Guidebook

Some of the most notable advantages include:

Enhanced precision and consistency:

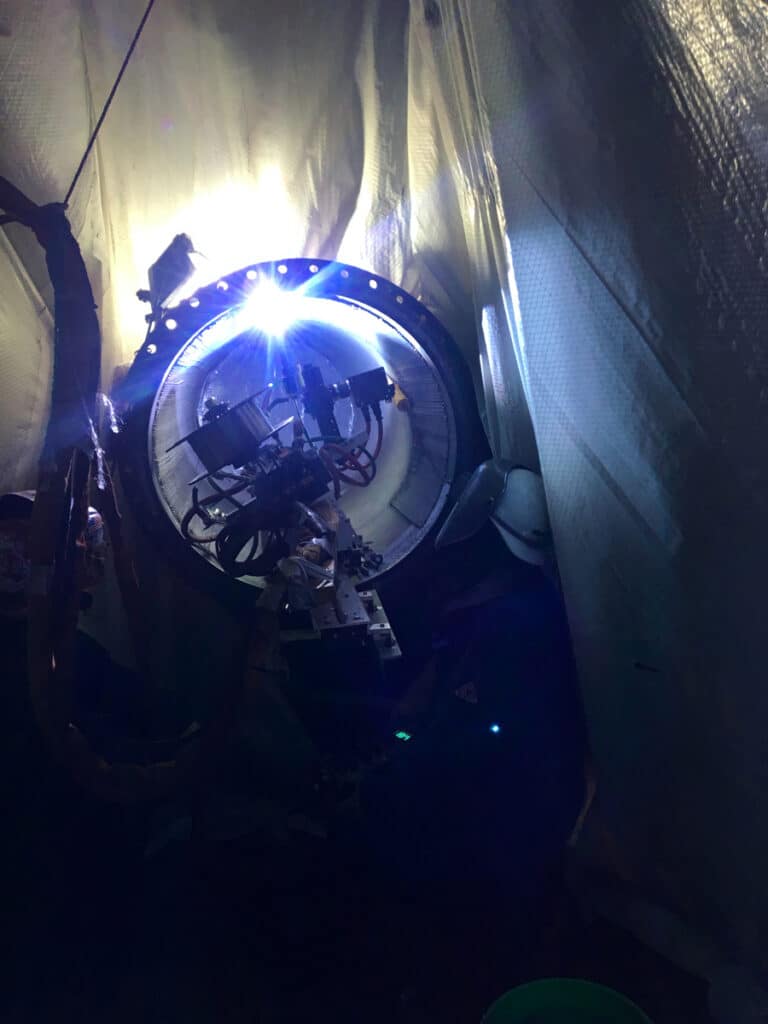

Automated welding systems use advanced sensors, cameras, and control mechanisms to ensure precise welds with no human error.

This results in stronger, more reliable welds with fewer defects and failures.

Increased productivity and efficiency:

Automated welding systems can work at much faster speeds than human welders, reducing production times and benefiting construction companies and their clients with shorter project timelines.

They also have the advantage of being able to operate continuously without fatigue, leading to less downtime and increased productivity.

Improved safety and working conditions:

Automating the welding process significantly reduces the risk of accidents and injuries that can occur due to the inherent dangers of welding, such as high temperatures and hazardous materials.

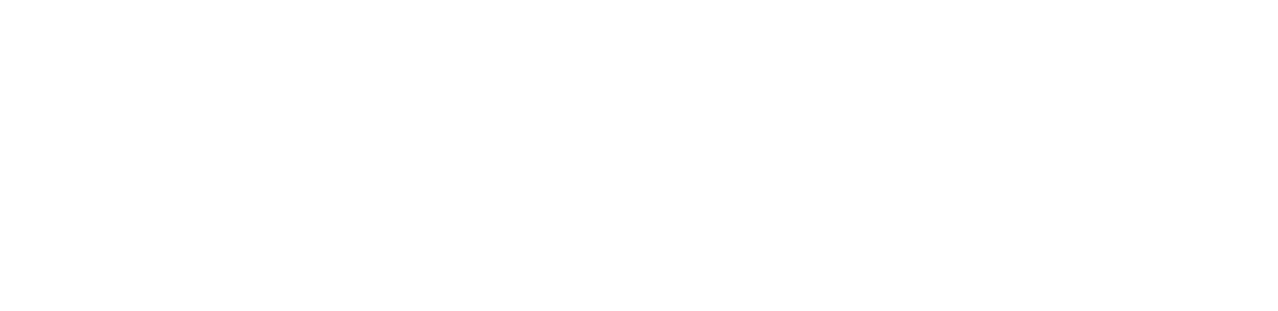

Automated systems can also work in environments that are too dangerous or inhospitable for humans, such as confined spaces or areas with toxic gases, minimizing the risk of long-term health problems associated with exposure to these conditions.

Cost-effectiveness:

Although the upfront cost of investing in automated welding systems can be significant, the long-term labor cost savings can offset the initial expense by reducing the number of skilled welders needed and associated training and retention costs.

Additionally, automated systems minimize material waste by precisely controlling the amount of filler material used in each weld, resulting in lower material costs and a more sustainable and environmentally friendly construction process.

Environmental benefits:

Automated welding systems are generally more energy-efficient than manual welding processes, thanks to their precise control and faster operating speeds. This reduction in energy consumption leads to lower greenhouse gas emissions and a smaller environmental footprint.

Furthermore, by minimizing material waste and reducing the need for rework, automated welding systems help decrease the amount of waste generated during the construction process, contributing to a cleaner and more sustainable environment.

Applications of Automated Welding Technology

The advantages of automated welding technology make it an attractive option for a wide range of industries.

Some of the most prominent applications include:

Oil and gas industry:

Refineries play a crucial role in processing crude oil and natural gas into usable fuels and other valuable products. Automated welding technology can be used to streamline the construction and maintenance of refinery components, resulting in faster project completion times and more reliable infrastructure.

The complex structures and equipment within refineries, such as pressure vessels and heat exchangers, require specialized welding techniques to ensure durability and to withstand harsh operating conditions. Automated welding systems can perform these tasks with greater precision and consistency, contributing to increased efficiency and safety in refinery operations.

Building and infrastructure construction:

Steel is a common material used in the construction of buildings, bridges, and other infrastructure projects. Automated welding technology enables faster and more accurate construction of these structures, resulting in reduced project timelines and improved overall quality.

The construction of bridges and tunnels often involves complex welding tasks that require high levels of precision and quality. Automated welding systems can perform these tasks more efficiently and accurately than human welders, ensuring the structural integrity and longevity of these critical infrastructure components.

Automotive industry:

Automated welding plays a crucial role in the mass production of automobiles, as it allows for rapid and precise assembly of vehicle bodies. This technology not only enhances the efficiency of the production process but also ensures the consistency and quality of each vehicle produced. In addition, exhaust systems require precise welding to ensure proper functioning and compliance with emissions regulations.

Automated welding technology enables the accurate and efficient production of these systems, resulting in improved performance and reduced environmental impact.

Aerospace industry:

The aerospace industry demands exceptionally high-quality welds to ensure the safety and performance of aircraft. Automated welding systems can deliver the necessary precision and consistency required in this industry, leading to more reliable and durable aircraft.

Rockets and satellites require specialized welding techniques to withstand the extreme conditions of space. Automated welding technology can provide the necessary precision and quality for these critical components, ensuring the success of space missions and the longevity of satellite systems.

Manufacturing and fabrication:

Heavy machinery used in industries such as mining, agriculture, and construction requires strong and durable welds. Automated welding technology allows for the efficient and accurate production of these machines, ensuring their reliability and performance in demanding environments.

In the fabrication of sheet metal components for a wide range of industries, including automotive, aerospace, and consumer goods, automated welding systems enable the rapid and accurate production of high-quality parts, streamlining the manufacturing process and reducing lead times.

Challenges and Limitations of Automated Welding Technology

Despite its numerous advantages, automated welding technology also faces certain challenges and limitations:

High initial investment costs:

The initial cost of acquiring and implementing automated welding systems can be substantial, potentially posing a barrier for smaller companies or those with limited budgets.

However, the long-term savings in labor and material costs can often offset this initial investment.

The complexity of integrating automation into existing processes:

Integrating automated welding systems into existing production processes can be complex, requiring careful planning and coordination.

Companies may need to invest in additional training and support to ensure a seamless transition to automation.

Skill gap and workforce retraining:

The shift to automated welding technology may result in reduced demand for skilled welders, potentially leading to job displacement.

Companies must be proactive in providing retraining and upskilling opportunities for affected workers, helping them transition to new roles within the organization.

Technological limitations in complex and unstructured environments:

While automated welding systems excel in structured environments, such as assembly lines or predetermined welding tasks, they may struggle to adapt to more complex or unstructured environments, where variables and conditions can change rapidly. In these situations, the expertise and adaptability of skilled human welders still play a crucial role.

The Future of Automated Welding Technology

As advancements in robotics, artificial intelligence, and machine learning continue to progress, the potential applications and capabilities of automated welding technology will only expand. Adaptive welding systems that can adjust in real-time to changing conditions and variables are already under development, enabling even greater levels of precision and efficiency.

Moreover, as machine learning algorithms improve, automated welding systems may become capable of learning and optimizing their own welding techniques, further enhancing their performance.

In addition to expanding its applications within existing industries, automated welding technology is also likely to find new applications in emerging industries, such as renewable energy, robotics, and advanced materials manufacturing.

As the world becomes increasingly reliant on automation and advanced technologies, the role of human workers in the welding process will continue to evolve, with a focus on skills such as programming, maintenance, and system design.

Conclusion

The advantages and applications of automated welding technology are transforming the mechanical construction industry, offering benefits such as enhanced precision, increased productivity, improved safety, and cost-effectiveness. This technology has a wide range of applications, from refinery maintenance to the automotive and aerospace industries, and holds the potential to revolutionize the way we build and maintain our world.

However, it is essential to acknowledge the challenges and limitations associated with automated welding technology, such as high initial investment costs, the complexity of integration, and the need for workforce retraining. As technology continues to advance and overcome these challenges, it will play an increasingly important role in shaping the future of mechanical construction.

In conclusion, embracing automated welding technology is essential for companies looking to remain competitive in the rapidly evolving construction landscape. By investing in this technology and preparing their workforce for the changes it brings, businesses can harness the transformative potential of automation to create a safer, more efficient, and sustainable future for the mechanical construction industry.

Unlock the Power of Nooter’s Automated and Semi-Automated Welding Services

Discover the advantages of partnering with Nooter for your most challenging welding projects.

With over 125 years of experience, state-of-the-art equipment, and a commitment to quality, Nooter offers customized automated and semi-automated welding solutions to help you achieve improved weld quality, increased output, repeatability, decreased scrap, reduced labor costs, and safer working conditions.

Don’t miss out on the opportunity to revolutionize your construction processes – contact Nooter Specialty Services today and experience the difference that cutting-edge welding technology can make for your business.