The Mechanical Construction Guidebook

In the industrial, commercial, and residential sectors, mechanical construction plays a variety of important roles.

Any contractor will come across mechanical construction at some point or another, whether it’s a residential builder installing heating and cooling in a newly built house, or an industrial contractor installing a waste to energy boiler at a refinery.

The purpose of this post is to educate you about Mechanical Construction, what it is, its history, examples, codes and standards, and resources for those of you who want to learn more about it.

The main focus will be on the industrial and commercial sectors.

What is Mechanical Construction?

The role of a mechanical contractor is to oversee the installation, maintenance, and repair of mechanical systems and equipment within a project.

These systems may include:

- Heaters

- Furnaces

- Ducts

- Boilers

- Chillers

- Heat Exchangers

- Piping: Learn more about piping

- Plumbing

- Pressure Vessels: Learn more about pressure vessels

- Storage Tanks

- Structural Steel

To name a few.

Contractors who specialize in mechanical work are responsible for everything that involves mechanical parts, including manufacturing and installing mechanical and automated systems. Maintenance and repairs can also be handled by a mechanical contractor once the system is installed.

Mechanical equipment installation requires a great deal of experience due to the high cost, danger, and complexity of these projects.

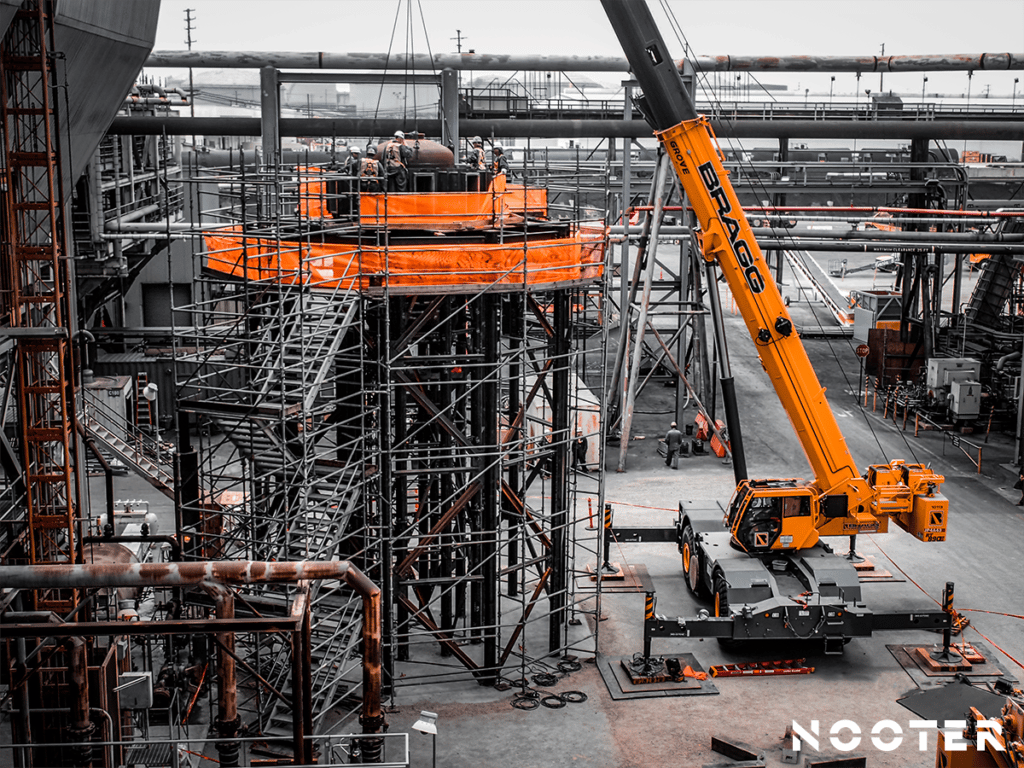

Heat exchangers, boilers, and fluid catalytic cracking units are all heavy pieces of equipment that need major safety precautions, experienced rigging engineers, and cranes to be successfully installed.

An experienced contractor will have the knowledge and experience of planning, scheduling, safety, and rigging to make sure your equipment is installed safely and on schedule.

Most mechanical equipment requires preventive maintenance. Predictive maintenance, scheduled maintenance, and inspections all fall under this category. The purpose of preventive maintenance is to identify potential failures and determine the time when preventive action should be taken before a functional failure occurs.

In essence, a mechanical contractor solves problems and redesigns mechanical systems that aren’t performing adequately or efficiently.

The History of Mechanical Construction

It is obvious that mechanical engineering must be mentioned when discussing the history of mechanical construction.

Mechanical engineering and construction is all about machines, how they function, how they can be improved, and how they can improve work capacity.

A mechanical system is designed, analyzed, and manufactured using the principles of physics, engineering, mathematics, and material science. The industry includes everything that makes our modern lives possible, from machines to power systems, from factory production lines to computers to boilers and pressure vessels.

The Industrial Revolution marked the beginning of mechanical engineering and construction as we know it today.

The world of mechanical engineering opened up incredible possibilities as humans became more dependent on machines to increase work output and improve production efficiency.

Steam engines played a pivotal role in the industrial revolution.

As a result of James Watt’s invention of the steam engine, many more significant innovations of the industrial revolution and beyond followed. Watt is thus often called the father of mechanical engineering. Largely due to his invention, mechanical engineering became a profession.

After the steam engine, steam locomotives and self-propelled boats became popular modes of transportation. Rail and canal tracks were soon to be formed in a rapidly growing network.

Several years later, the invention of the automobile also grew the need for mechanical engineers, especially at a time when automotive technology was still in its infancy.

As a result of all these inventions, mechanical engineers along with mechanical contractors and fabricators were needed to install, fabricate, and maintain the equipment supporting mass production of these new technologies.

10 Terms to Know

- Scope of Work: A written statement or list of tasks, reached through consultation with department personnel and defines the actual work to be done. It is presented to the department either on a drawing or as a separate document.

- Estimate: An approximation of the expected cost to complete the work/project as outlined in the scope of work

- Critical Path: The set of activities that must be completed on time for the project completion date to be met. Activities on the critical path have no slack time.

- Change Order: A written document between the owner and the contractor signed by the owner and the contractor authorizing a change in the work or an adjustment in the contract sum or the contract time.

- Time and Materials (T&M): A written agreement between the owner and the contractor wherein payment is based on the contractor’s actual cost for labor, equipment, materials, and services plus a fixed add-on amount to cover the contractor’s overhead and profit.

- Critical Lift: A lift that exceeds 75% of the rated capacity of the crane. It could also mean that the load is so heavy that it requires more than one crane to be properly moved.

- Capital Construction Project: Any project in which the total budget exceeds $632K

- Request for Information (RFI): A written request from a contractor to the owner or architect for clarification or information about the contract documents following contract award.

- Request for Proposal (RFP): A RFP is a solicitation made, often through a bidding process, by an agency or company interested in procurement of a commodity, service or valuable asset, to potential suppliers to submit business proposals.

- Specifications: A detailed, exact statement of particulars, especially statements prescribing materials and methods; and quality of work for a specific project.

7 Examples of Mechanical Construction Projects

Mechanical contracting involves troubleshooting, redesigning, and installing faulty systems, as well as maintaining and repairing them.

Depending on the needs of the particular project, you will commonly see mechanical contractors performing the following:

- Fabrication and installation of structural steel includes catwalks, ladders, platforms, grating, and pipe support beams, among others.

- Upgrades, repairs, demolition, and new equipment installation.

- A range of industrial equipment installation services, from full-scale plant relocations to equipment installations and alignments.

- Commercial and industrial HVAC services include installing, repairing, or replacing air handling units, chillers, fans, boilers, valves, ductwork, pumps, and other equipment.

- In the food and beverage, pharmaceuticals, and personal care industries, sanitary piping is made by precision welding to create clean, sealed pipes, valves, and fittings.

- Chemical and food processing, power generation, wastewater treatment, refining, and potable water production all use process and utility piping.

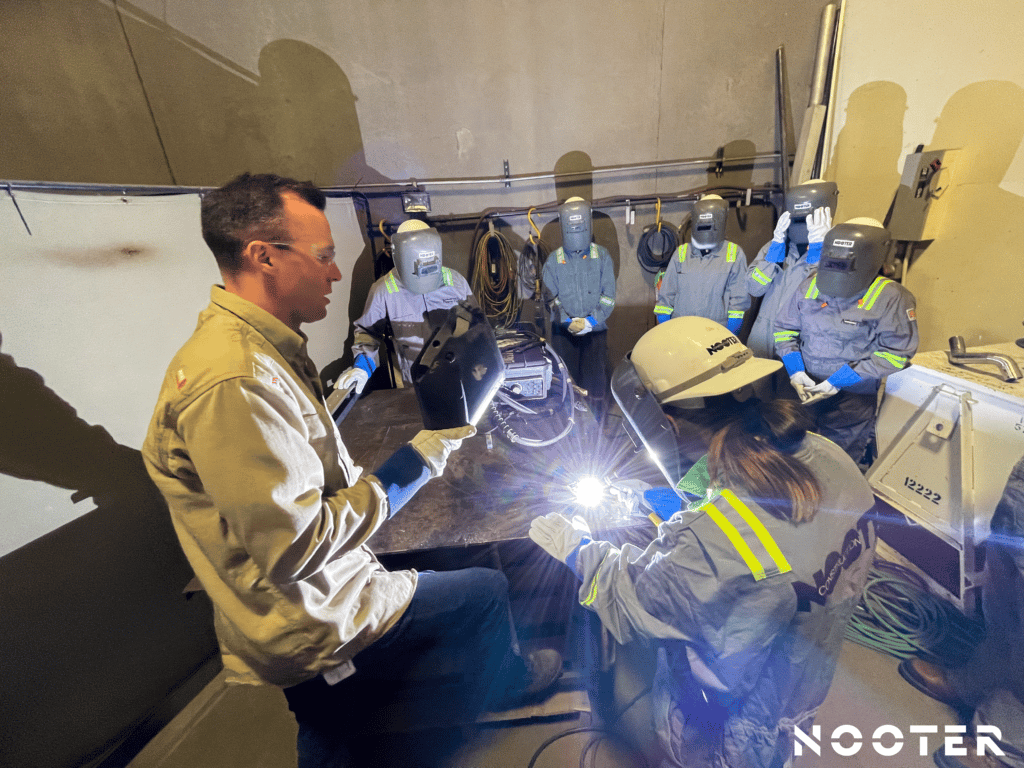

- Welding and Specialty Welding Services ensure that boiler and pressure vessel repairs comply with NBIC and ASME regulations.

Codes and Standards in Mechanical Construction

The American Society of Mechanical Engineers (ASME) codes and standards are followed when performing mechanical construction, welding, and engineering.

Since 1915, these codes and standards have enabled collaboration, knowledge sharing, and skill development across all engineering disciplines, promoting the crucial role of engineers in society.

Note: ASME was founded in 1880 but the first boiler code was written in 1915.

Learn more about The American Society of Mechanical Engineers Here

To ensure that these codes and standards are implemented and followed, mechanical contractors typically have a quality assurance and quality control department.

For example:

NOOTER is authorized by the American Society of Mechanical Engineers (ASME) for the manufacture and assembly of ASME Section I Power Boilers and Piping (“S” and “A”) and for the manufacture of ASME Section VIII, Division 1 and 2 Pressure Vessels (“U” and “U2”).

Additionally, NOOTER is authorized by the National Board of Boiler and Pressure Vessel Inspectors to Perform Repairs and alterations to power boilers and pressure vessels (“R”).

A company is only as strong as its QA/QC and Safety program.

Learn about Nooter’s QA/QC Here

Summary

A mechanical contractor oversees the installation, maintenance, and repair of mechanical systems and equipment within a project.

Its history predates the industrial revolution but the need for mechanical engineers, and contractors increased dramatically with the invention of steam engines, boats, trains, and automobiles during this time period.

The ASME codes and standards are one of the most important aspects of mechanical engineering and construction.

Mechanical Construction and ASME Code Experts

NOOTER has been providing mechanical construction and ASME code welding services to the industrial and commercial sectors for over 125 years.

See Mechanical Construction Services

With more welding procedures than pages in a Harry Potter book and some of the most experienced rigging engineers on the planet, we have the solutions you need!

Ask us a question about mechanical construction!