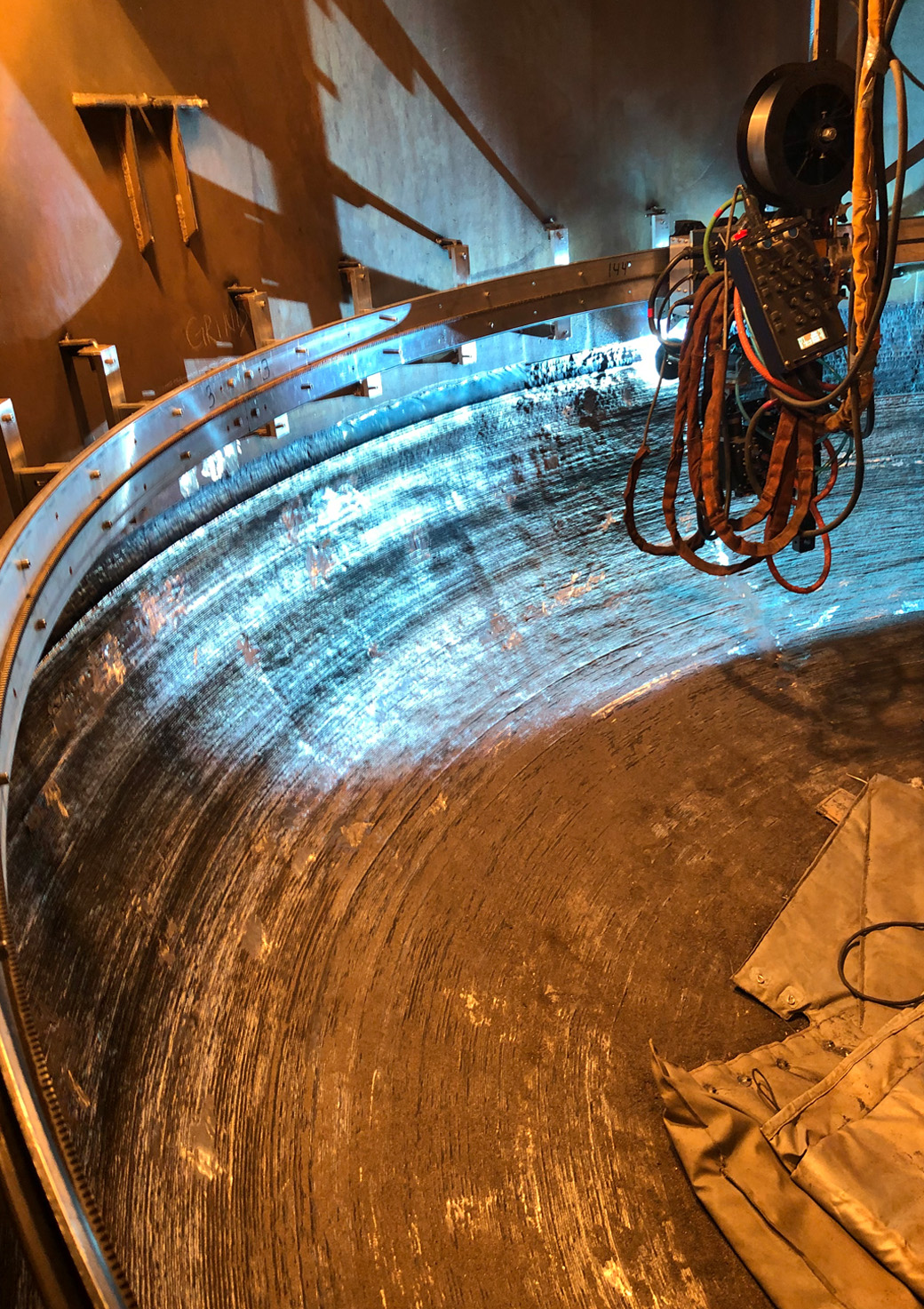

Specialty Welding Services

NOOTER uses the industry’s most advanced equipment to provide automated and semi-automated welding services for the toughest welding projects nationwide.

NOOTER Specialty Services

Using over 125 years of welding experience, NOOTER has developed and customized automated and semi-automated welding procedures, techniques, and equipment that help us consistently solve welding challenges efficiently and effectively.

Benefits of Automated and Semi-Automated welding:

- Improved Weld Quality

- Increased Output

- Repeatability

- Decreased Scrap

- Decreased Variable Labor Costs

- Safer Working Conditions