Ready, Set, Maintenance: Planning & Scheduling Your Next Turnaround

Ready, Set, Maintenance: Planning & Scheduling Your Next Turnaround

It happens once a year or every few years, but every company faces the same dilemma: how do we keep our equipment running smoothly and efficiently while ensuring that our employees are safe? The answer is through proper maintenance planning and scheduling. By creating a plan and schedule specifically for your next turnaround, you can avoid costly downtime and ensure that your equipment is ready to go when you need it most.

The importance of proper maintenance planning and scheduling

The importance of a well-executed maintenance turnaround cannot be overstated. The amount of money, time, and effort that goes into planning and scheduling a proper maintenance turnaround is significant. The unfortunate reality is that too often turnarounds are not given the attention they deserve and end up being rushed, resulting in subpar workmanship and potential safety hazards. A properly planned and executed maintenance turnaround will not only save money in the long run but also ensure a safer work environment for everyone involved.

How to create a plan and schedule for your next turnaround

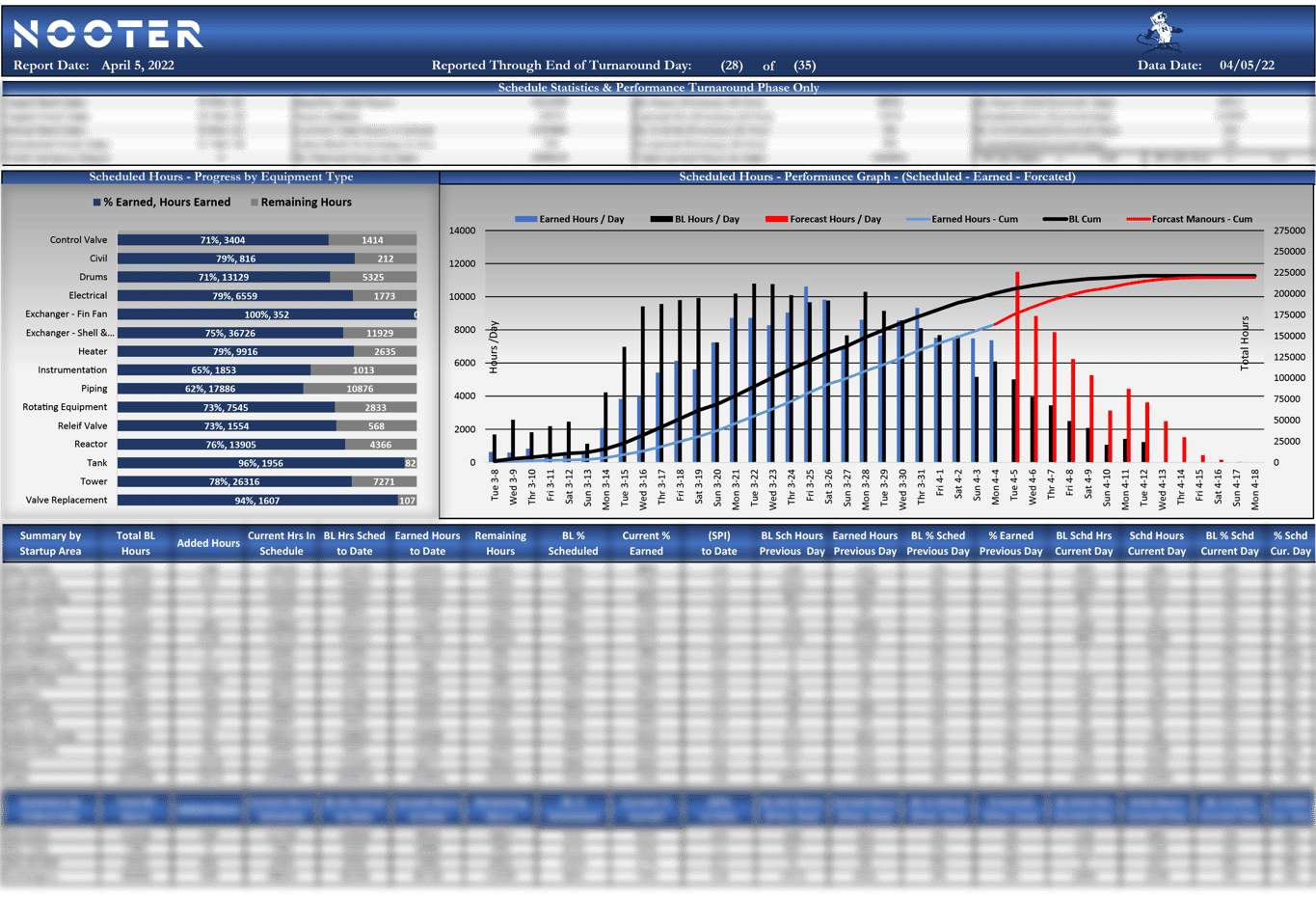

When it comes to maintenance turnarounds, the key is planning and scheduling. By properly planning and scheduling your turnaround, you can ensure that everything runs smoothly and efficiently. Here are a few tips on how to create a plan and schedule for your next turnaround: First, start by creating a timeline of all the tasks that need to be completed during the turnaround. Nooter’s planners and schedulers utilize Primavera P6 mixed with custom excel sheets to display your timeline and schedule (see image 1A). This will help you stay organized and on track. Make sure to allow enough time for each task, as rush jobs are often one of the main causes of delays during turnarounds.

The benefits of having a plan and schedule specifically for your equipment

Your equipment is one of your most important assets. By taking the time to create a specific plan and schedule for maintaining it, you can prolong its life and keep it running at peak performance. Doing regular maintenance on your equipment can save you money in the long run by avoiding unexpected repairs or replacements. Scheduling regular maintenance check-ups for your equipment helps ensure that any issues are caught early, before they have a chance to cause expensive damage.

Image 1A: Daily Dashboard Snapshot

The planners and schedulers at Nooter are among the most talented in the business. Having over 126 years of experience in the industry, we are sure to have a plan that works for you.

Turnaround Planning Services Include

- Constructability Reviews

- Estimating and Scheduling

- Execution Planning

- Logistics Planning

- Safety Planning

- Quality Planning

- Manpower Planning

For my information on our Turnaround Planning Services please click on the link below https://cicgroup.com/nooter/services/turnarounds/