4 Common Welding Processes Used in Industrial Construction

4 Common Welding Processes Used in Industrial Construction

Welding plays a pivotal role in the realms of industrial construction, bridging gaps, and joining metals to erect towering structures, lay extensive pipelines, and construct a wide array of metallic assemblies. With a multitude of welding processes available, each brings its unique advantages and specialties to the table.

This blog aims to unveil the intricacies of four fundamental welding processes commonly deployed in industrial construction: Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW/TIG), and Flux-Cored Arc Welding (FCAW).

Dive into each section to unravel the core characteristics, common applications, advantages, and disadvantages of each welding process.

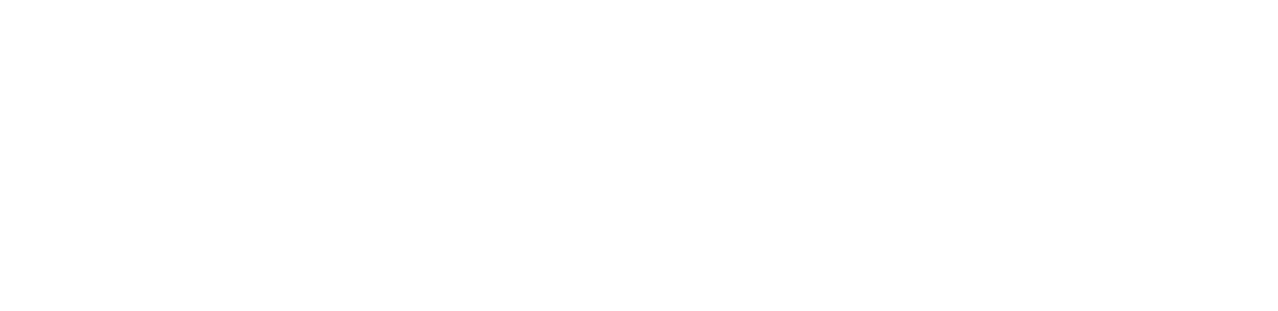

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW) is a manual arc welding process that uses a consumable electrode covered with a flux to deposit the weld. An electric current, in the form of either alternating current or direct current from a welding power supply, is used to form an electric arc between the electrode and the metals to be joined. As the weld is deposited, the flux coating of the electrode melts and vaporizes, giving off vapors that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination.

How to Make a Quality Shielded Metal Arc Weld

Common Uses and Applications of Shielded Metal Arc Welding (SMAW):

- Construction Industry

- Industrial Fabrication

- Shipbuilding

- Automotive and Transportation

- Repair and Maintenance

- Oil and Gas

- Military and Defense

- Boiler and Pressure Vessel Fabrication

Advantages of Shielded Metal Arc Welding (SMAW)

- Versatility

- Portability

- Low Cost

- Less Sensitivity to Atmospheric Conditions

- Simple Equipment

Disadvantages of Shielded Metal Arc Welding (SMAW)

- Slag Removal

- Consumable Electrodes

- Lower Deposition Rates

- Fume Generation

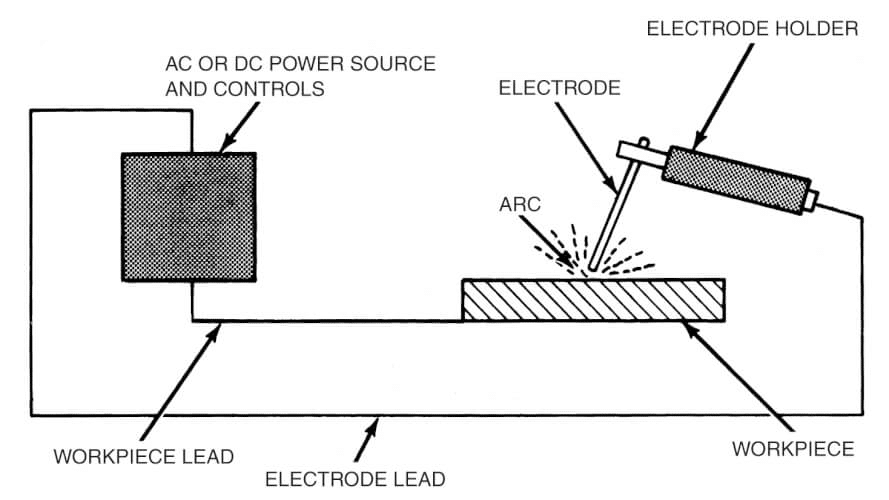

Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding (GMAW), commonly referred to as Metal Inert Gas (MIG) welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join. A continuous solid wire or metal cored wire electrode is fed through a welding gun, along with a shielding gas that protects the weld pool from contaminants present in the surrounding atmosphere.

Creating a Safe Environment While Gas Metal Arc Welding

Common Uses and Applications of Gas Metal Arc Welding (GMAW)

- Automotive Industry

- Manufacturing

- Construction

- Shipbuilding

- Oil and Gas

- Aerospace

- Robotics and Automation

- Additive Manufacturing

- Repair and Maintenance

Advantages of Gas Metal Arc Welding (GMAW)

- High Productivity

- Cleaner Welds

- Versatility

- Ease of Learning

- Adaptability

- Easily Automated

Disadvantages of Gas Metal Arc Welding (GMAW)

- Shielding Gas Sensitivity

- Equipment Cost

- Portability

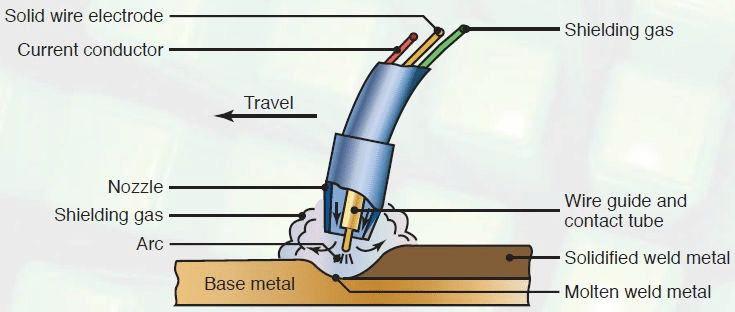

Gas Tungsten Arc Welding (GTAW/TIG)

Gas Tungsten Arc Welding (GTAW), commonly referred to as Tungsten Inert Gas (TIG) welding, is a process that uses a non-consumable tungsten electrode to produce an arc. The weld area is protected from atmospheric contamination by an inert shielding gas, such as argon or helium, and a filler metal is normally used, though it is not always necessary.

Recommended Practices for Gas Tungsten Arc Welding

Common Uses and Applications of Gas Tungsten Arc Welding (GTAW/TIG)

- Aerospace Industry

- Nuclear Industry

- Art and Sculpture

- Automotive and Motorsport

- Oil and Gas

- Pipe and Tube Welding

- Bicycle Manufacturing

- Tool and Die Making

- Repair and Maintenance

Advantages of Gas Tungsten Arc Welding (GTAW/TIG)

- High-Quality Welds

- Versatility

- Suitable for Thin Materials

- No Spatter

- Precise Control

Disadvantages of Gas Tungsten Arc Welding (GTAW/TIG)

- Requires High Skill Level

- Lower Deposition Rates

- Sensitivity to Contamination

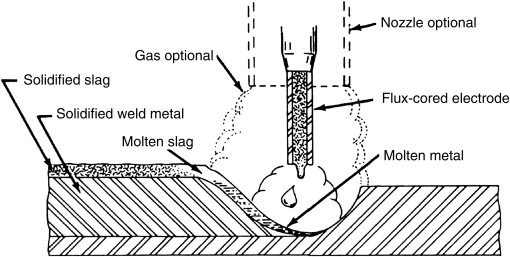

Flux-Cored Arc Welding (FCAW)

Flux-Cored Arc Welding (FCAW) is a welding process that uses a tubular wire electrode filled with a flux compound that protects the weld pool by producing a shielding gas when the flux inside the wire is melted. Similar to SMAW, the melted flux produces vapors that form a shielding gas and a slag that protects the molten weld puddle. FCAW can be used with or without an externally supplied shielding gas, depending on the specific wire being used.

Common Uses and Applications of Flux-Cored Arc Welding (FCAW)

- Construction

- Heavy Equipment Manufacturing

- Shipbuilding and Repair

- Railroad

- Oil and Gas

- Offshore and Pipeline

- Military and Defense

- Structural Steel Erection

Advantages of Flux-Cored Arc Welding (FCAW)

- High Deposition Rate

- Portability

- Suitable for Outdoor Conditions

- Capable of Welding Thick Materials

- Flexibility

Disadvantages of Flux-Cored Arc Welding (FCAW)

- Fume Generation

- Spatter

- Slag Removal

- Limited Suitable Metals

Future of Automated Welding

Automated welding is on the cusp of a technological transformation. The integration of AI and machine learning promises smarter systems. AI-driven predictive maintenance can foresee equipment needs, minimizing downtime, while machine learning refines welding techniques, ensuring optimal results with every use.

The scope of automated welding will expand, finding relevance in diverse sectors, from aerospace to underwater construction. However, these advancements also spotlight the need for specialized training. As manual roles decrease, the demand for expertise in system oversight and advanced maintenance will rise. Educational institutions will likely adapt, tailoring curricula to these evolving industry needs.

In a nutshell, the future sees automated welding seamlessly blending cutting-edge technology with human specialization.

Conclusion

Each process holds its unique prominence, specializing in various applications ranging from construction and automotive to aerospace and military defense.

By understanding the diverse facets and applications of these welding processes, one can select the most suitable method for achieving optimal results in their specific welding projects.

Choose NOOTER for Your Next Welding Project

Harness our unrivaled expertise and tradition of quality and safety to ensure the success and durability of any challenge.

Choose NOOTER – where history and craftsmanship forge extraordinary outcomes.