Project Overview & Customer Challenge

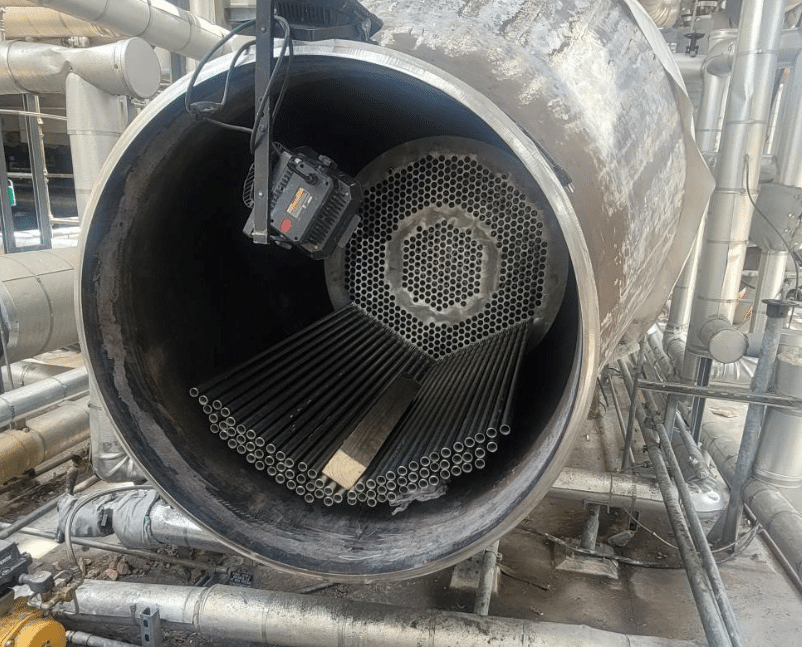

The unit’s IP RAC was becoming a frequent source of maintenance headaches due to persistent tube-to-tube sheet joint leaks. These ongoing issues not only impacted system performance but also created reliability risks that required repeated attention from the plant’s maintenance team.

Over time, these leaks contributed to unplanned outages, increased maintenance costs, and reduced confidence in the unit’s overall integrity. The plant was seeking a long-term solution to restore operational stability, reduce downtime, and improve serviceability of the affected section.

Nooter Eriksen’s Aftermarket team was brought in to provide a comprehensive solution that would not only address the immediate mechanical issues, but also improve accessibility for future inspections and repairs — aligning with the plant’s broader asset management goals.

Our Approach

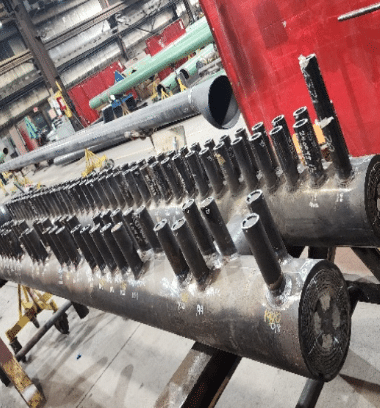

Our team developed a solution centered on replacing the degraded internal components—primarily the tube sheets and baffles—with newly fabricated parts that matched the original OEM specifications. This ensured full compatibility and restored the mechanical integrity of the affected section.

In addition to the replacement scope, we identified an opportunity to enhance long-term maintainability by incorporating a new tube-side manway into the component design. This access point would allow plant personnel to perform future inspections and maintenance more easily, improving outage efficiency and reducing manual labor requirements.

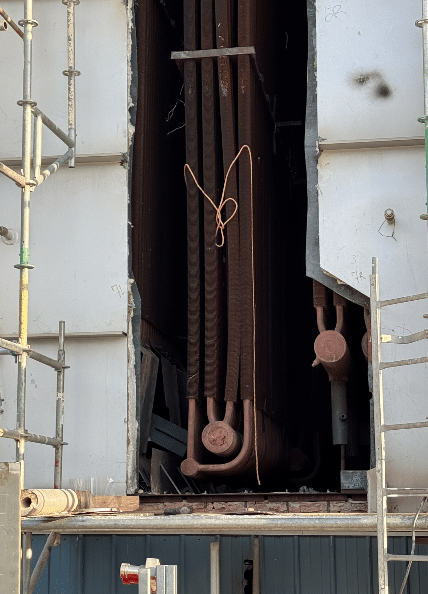

To optimize quality and minimize onsite disruption, the tube-side section was carefully removed and shipped to a controlled shop environment for fabrication and manway installation. This off-site approach allowed for greater precision in fabrication, better welding conditions, and reduced field work hours during reinstallation. Once complete, the upgraded components were reinstalled, restoring the unit to full operation.

Challenges & Results

Executing this type of upgrade presented a number of technical and logistical challenges that required detailed planning and experienced project management:

- Alignment with OEM design: All replacement components needed to be fabricated to original specifications to ensure proper fit and function under high-temperature, high-pressure conditions.

- Field-to-shop coordination: The process of removing, transporting, and reinstalling the large tube-side section required precise handling and close coordination between field and shop operations.

- Schedule sensitivity: The work was performed under a tight outage window, necessitating disciplined execution and minimal rework to avoid delaying the plant’s return to service.

- Quality assurance: Performing manway installation in a shop environment required detailed planning and inspection to maintain welding quality and code compliance, while still aligning with project timelines.

The project delivered measurable, long-term improvements:

- Reduced downtime: By eliminating leak-prone joints, the unit is now less likely to require frequent, costly repairs.

- Extended asset life: Restoring critical components to original design integrity while adding access improvements increases long-term system reliability.

- Improved maintainability: The newly installed manway enhances future access for inspection and maintenance, simplifying outage work and reducing labor hours.

- High-quality execution: Shop-controlled fabrication of components ensured consistent quality and minimized field risk.

Partner With Us!

Our Aftermarket Engineering Team is ready to support your next outage or upgrade.