Project Overview & Customer Challenge

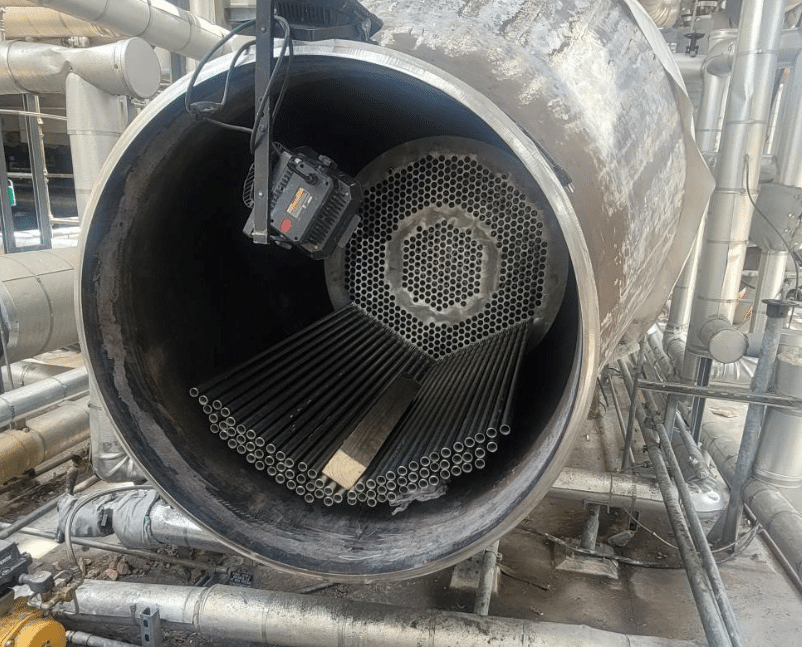

A customer approached Nooter Eriksen’s Aftermarket team with an ongoing issue in one of their HRSG units: the High-Pressure Superheater #1 (HPSH1) lower headers were showing signs of deterioration and had become a persistent problem area for tube leaks and reliability concerns.

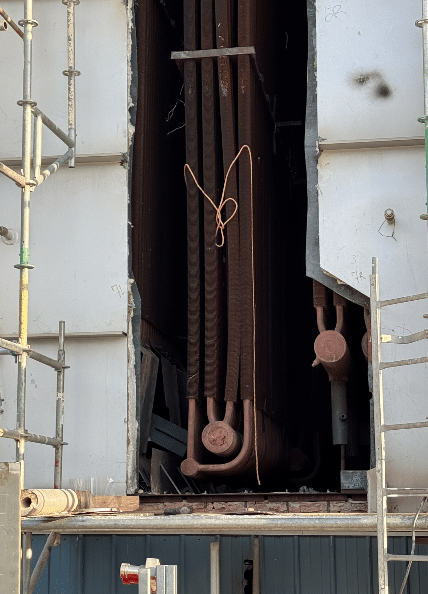

The original design used a staggered header configuration with bent tubes, which is known to introduce higher thermal and mechanical stress, increasing the likelihood of fatigue-related failures over time. In fact, 40 tubes had already been plugged due to previous issues — a clear signal that the original design had reached the limits of its usable life.

To avoid continued degradation and unplanned downtime, the customer needed a long-term solution that addressed both the mechanical weaknesses of the original layout and the previously modified condition of the bundle.

Our Approach

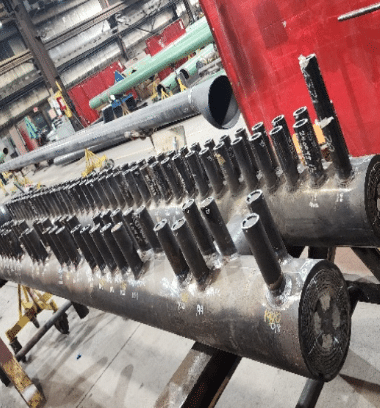

Nooter Eriksen provided a complete redesign, supply, and delivery of replacement HPSH1 lower header assemblies for one HRSG. The new design eliminated the problematic staggered header and bent tube arrangement by introducing a parallel header configuration with jumper pipes connecting the lower headers — reducing tube stress and improving flow alignment.

Because 40 tubes had previously been plugged, our engineering team retrieved and analyzed job records to locate the plug map, then worked closely with site personnel to confirm plug locations during outage prep. The new headers were fabricated without stubs in the plugged locations, ensuring compatibility with the as-found tube field and avoiding unnecessary complications during installation.

All design calculations and fabrication drawings were included as part of our deliverables to support future inspections, repairs, or replacements.

Challenges & Results

The successful execution of this project required detailed coordination and customized engineering:

- Legacy field condition management: With 40 tubes previously plugged, standard header fabrication was not feasible

- Plug map recovery and verification: Our team researched historical job records to identify the plug locations and worked with the client to verify the actual field condition

- Custom fabrication: The new headers were precisely fabricated without stubs at the plugged tube positions, ensuring proper fit-up and alignment during installation

- Design adaptation: Transitioning from a staggered header layout to a parallel configuration required careful design to maintain performance and mechanical integrity

This targeted upgrade provided the plant with both immediate improvements and long-term reliability gains:

- Extended asset life: New headers and a simplified tube configuration reduce fatigue and extend the useful life of the component

- Reduced leak risk: The parallel header design removes the stress concentrations caused by the prior bent tube geometry

- Improved system integrity: Custom header fabrication based on field conditions avoided rework and fit-up issues

- Confidence in future performance: With engineering-led design and site coordination, the customer received a tailored solution ready for long-term service

Partner With Us!

Our Aftermarket Engineering Team is ready to support your next outage or upgrade.