Executive Summary

As the energy industry undergoes a fundamental transformation, plant operators are being asked to do more with less—optimize output, decarbonize operations, and extend the life of aging assets—all while adapting to new fuel types, regulatory shifts, and digital expectations. In this environment, the role of the Original Equipment Manufacturer (OEM) has never been more critical.

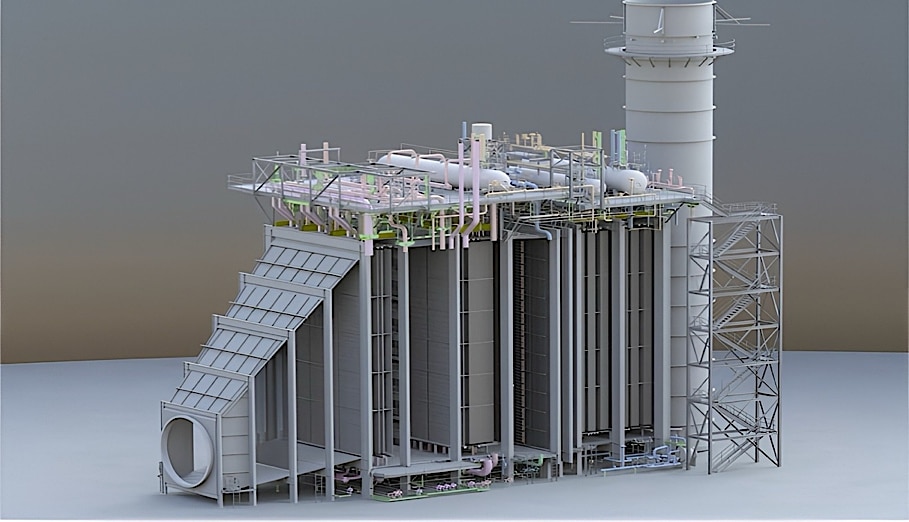

At Nooter Eriksen (NE), our deep engineering expertise, historical design knowledge, and global fleet experience enable us to provide actionable support in a landscape where generic solutions no longer suffice. This paper explores why working directly with the HRSG OEM is essential for maintaining asset integrity, operational flexibility, and long-term value in today’s dynamic energy market.

The HRSG Industry in Rapid Transition

Global power producers face a unique convergence of challenges:

- Fuel Transition: From natural gas to hydrogen blending and renewable integration

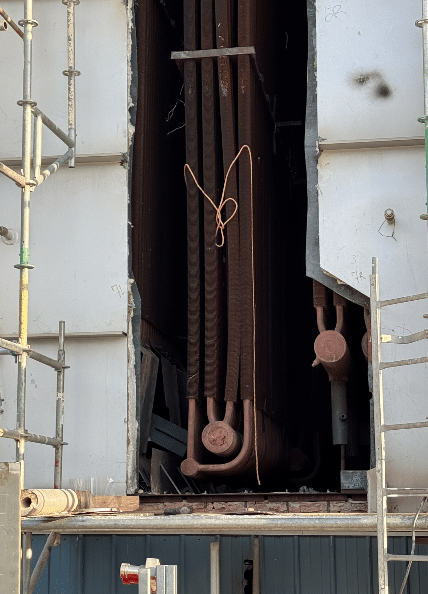

- Aging Infrastructure: HRSGs exceeding 20+ years in operation, many running beyond original design cycles

- Operational Flexibility Demands: Increased cycling, faster starts, and expanded load ranges

- Regulatory Pressure: Tightening emissions and safety compliance

- Talent Gaps: Loss of experienced plant personnel and engineering turnover

In this climate, plant teams need more than a supplier—they need a partner who understands their equipment inside and out.

OEM vs. Third-Party: The High-Stakes Difference

While third-party providers can offer attractive pricing, they often lack the design insight, fleet-wide data, and predictive modeling tools available to the OEM. Choosing a non-OEM path may result in:

- Mismatched thermal performance, leading to efficiency losses

- Improper material selection, risking premature failure or cracking

- Unvalidated design modifications, jeopardizing downstream equipment

- Limited support during commissioning and tuning

At NE, we maintain proprietary design tools and historical data for thousands of HRSGs worldwide allowing us to make informed decisions that protect both performance and safety.

The OEM Advantage, from Design to Operation

Engineering Continuity You Can Trust

- Access to as-built designs, including tube pitch, gas path flow distribution, and alloy specifications

- Ability to run design re-verification studies for upgrades, derates, or fuel shifts

- Deep familiarity with plant-specific constraints, such as support structure loading and thermal expansion behaviors

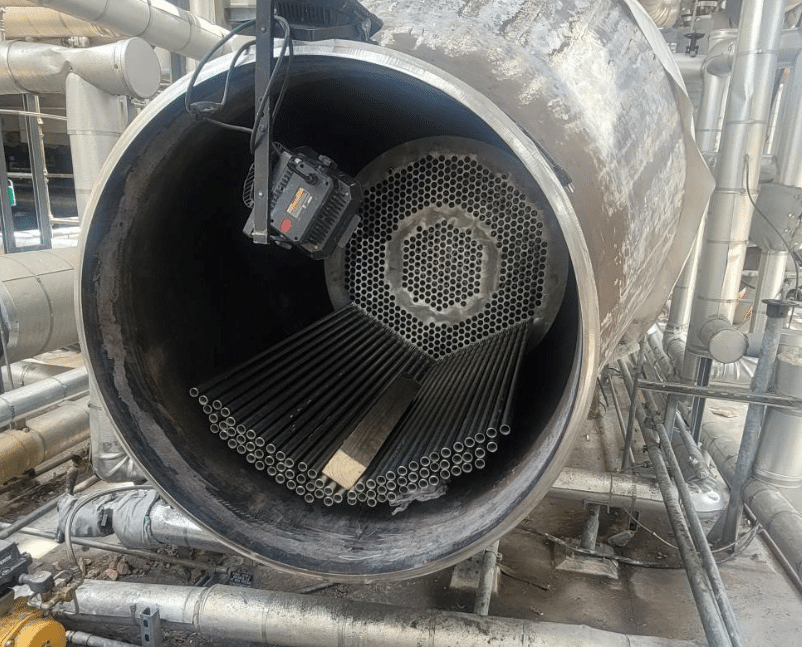

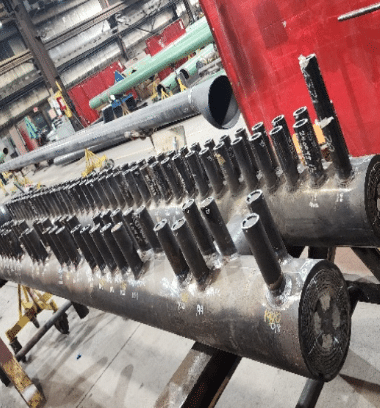

OEM Parts, Perfect Fit

- Accurate form-fit-function replacements that restore OEM design intent

- Metallurgy and weld specs matched to the original fabrication codes

- Pressure part design backed by ASME code compliance and NE quality assurance

Reducing Risk, Extending Life

- Fleet-wide data to predict wear patterns and component fatigue

- Upgrades designed to minimize outage time while maximizing return

- Inspection and evaluation services tailored to your HRSG’s original configuration

New Challenges, OEM Solutions

Engineering for Fuel Flexibility

As combustion conditions change, so do HRSG operating parameters. NE uses validated CFD and thermodynamic models to assess how new fuel profiles affect:

- Heat transfer rates

- Tube metal temperatures

- Catalyst performance and duct transitions

- Flow-induced vibration risks from volumetric flow shifts and steam density changes

- Impact of moisture content and hydrogen exhaust chemistry on cold-end corrosion

Adapting to Cycling & Fast Starts

Higher cycling rates increase thermal fatigue. NE provides:

- Tube stress analysis and life assessments

- Optimized header and tube replacements

- Drum levels and separator carryover rates

Staying Ahead on Emissions

As SCR and CO catalyst performance becomes more critical, NE offers:

- OEM-verified temperature window analysis

- Proper ammonia injection grid (AIG) placement and tuning

- Long-term support for low NOx conversion goals

Confidence in Any Condition

Whether adapting to emerging fuels, replacing aging coils, or navigating emissions regulations, working with the OEM ensures:

- Design-intent alignment with safety and performance goals

- Reduced outage risk through validated, proven solutions

- Long-term lifecycle planning based on fleet-wide data—not guesswork

At NE, we don’t just supply components—we engineer solutions tailored to your HRSG, your fuels, and your future.