Project Overview & Customer Challenge

Nooter Eriksen’s Aftermarket team was engaged to perform a turnkey replacement of the Feedwater (FWTR) Heater coil bundles, as part of a broader reliability and accessibility improvement project. Over time, the customer experienced decreased efficiency and increased maintenance complexity, particularly due to aging coil components and limited accessibility to critical valves and drain lines.

In addition to the bundle replacement, the plant needed modifications to the FWTR Heater to LP drum piping, specifically to improve access to key valves and simplify future maintenance. The existing metal bellows in the FWTR Heater drain lines also presented a reliability concern, prompting the need for a more robust, long-term solution.

Together, these issues pointed to the need for a comprehensive upgrade that would not only restore performance but also enhance the maintainability and longevity of key system components.

Our Approach

Nooter Eriksen provided a complete turnkey solution, managing the design, material supply, and field execution.

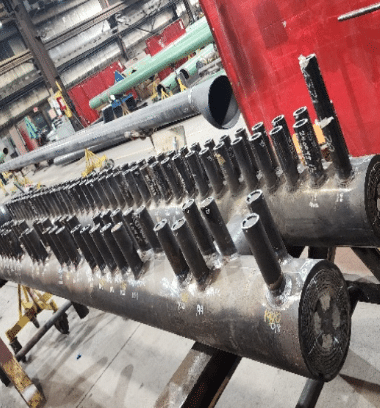

- Replacement of the existing FWTR Heater coil bundles with new units fabricated to meet OEM and plant performance standards.

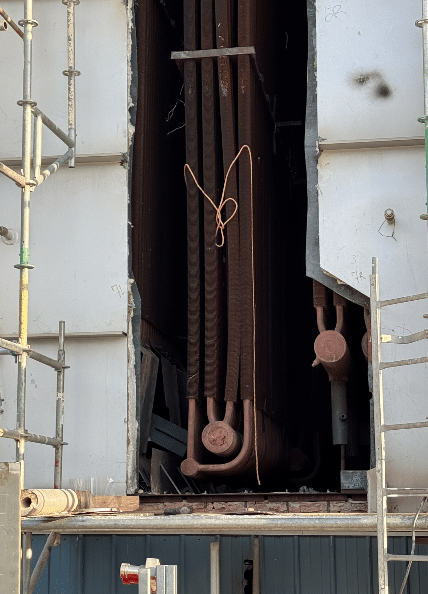

- Modifications to the FWTR Heater to LP drum piping line to reposition valves for easier access during routine operations and outages.

- Upgrade of the metal bellows in the FWTR Heater drain lines with Nooter Eriksen’s proven internal bellows design, engineered to improve flexibility and durability under cyclic conditions.

To ensure safe and efficient field execution, the installation strategy was specifically tailored to site constraints and the unique configuration of the HRSG. Our team worked closely with site personnel to deliver the project within the planned outage window while minimizing field risks and long-term maintenance needs.

Challenges & Results

This project involved several unique installation and logistical challenges that required innovative solutions:

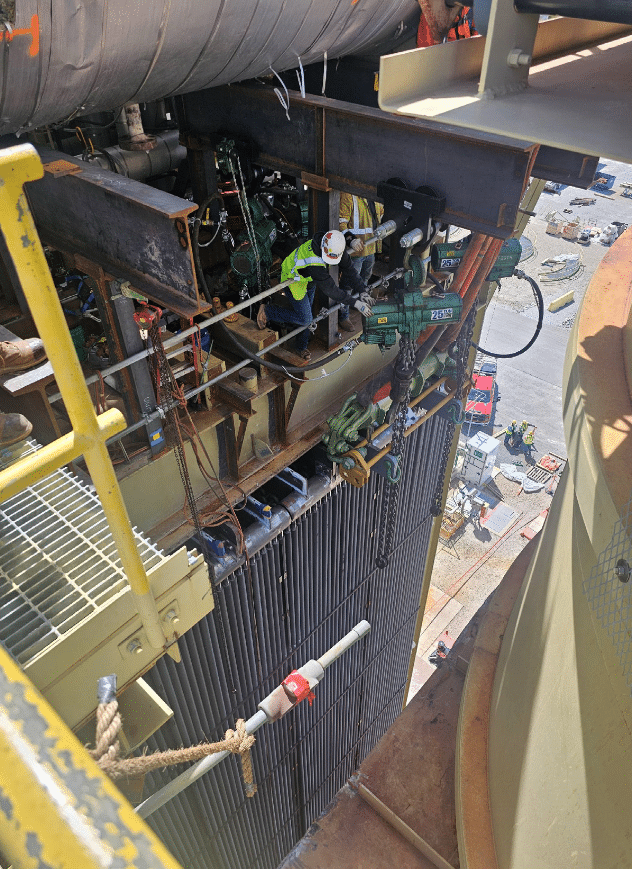

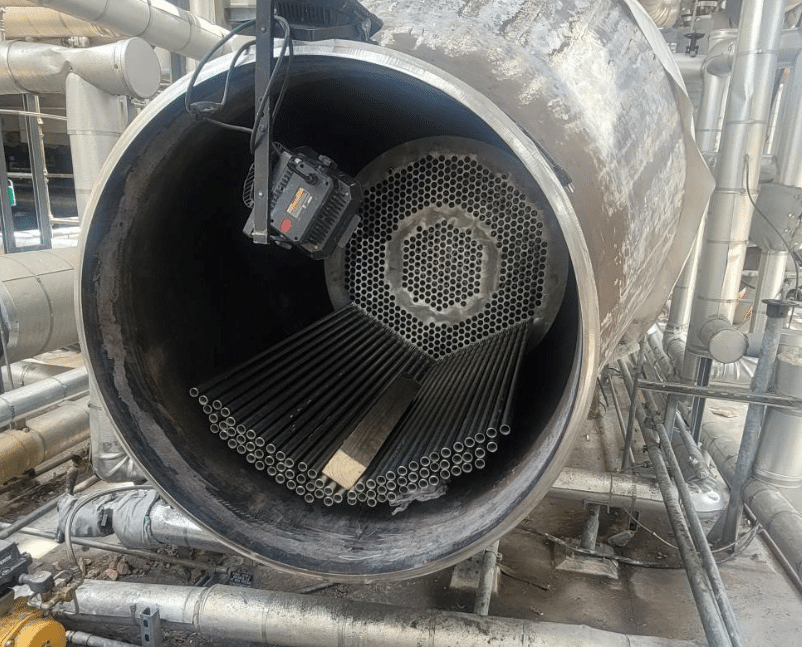

- Nonstandard coil installation path: Unlike typical coil bundle installations that are skidded, trolleyed in from the side, or dropped in through the roof, these coils had to be drifted in through the stack breeching sidewall.

- Specialized installation frame: The coils were temporarily suspended from a custom steel frame, which allowed for precise handling during the transition phase.

- Limited maneuverability inside the HRSG: Once inside, the bundles were trolleyed toward the front of the unit and pinned into place, requiring careful alignment and coordination due to space constraints.

- Multi-scope execution: The simultaneous execution of bundle replacement, piping modification, and bellows upgrade required tight planning and sequencing to stay within the outage schedule.

The project delivered multiple benefits to the plant, both immediate and long-term:

- Restored performance: The new FWTR coil bundles improved system thermal performance and reduced pressure drop.

- Enhanced access: FWTR Heater to LP drum valve modifications simplified routine maintenance, reducing labor hours and improving safety.

- Improved reliability: The upgraded internal bellows design enhances fatigue resistance and service life in high-cycle drain line applications.

- Custom-fit installation: The tailored installation method allowed for safe, accurate placement of the new bundles while accommodating the unit’s structural limitations.

- Minimized outage risk: A carefully planned execution strategy ensured all scopes were completed within the designated outage window.

Partner With Us!

Our Aftermarket Engineering Team is ready to support your next outage or upgrade.