Project Overview & Customer Challenge

Nooter Eriksen’s Aftermarket team successfully executed a turnkey upgrade and replacement of the Reheater #1 (RH1) coil bundles for a customer experiencing reliability and performance challenges. This project addressed critical design limitations of the existing system while improving future operational performance.

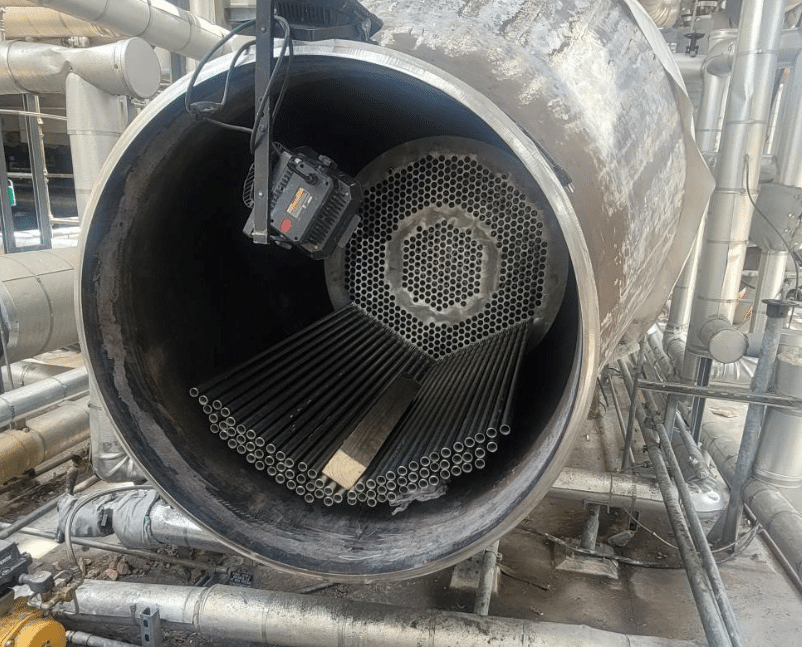

The customer was facing frequent failures and costly downtime due to an outdated RH1 header configuration. The original design featured:

- Staggered elevation upper and lower headers

- Bent tube geometry

- A mix of Grade 91 and Grade 22 materials

This configuration contributed to mechanical vulnerabilities and operational inefficiencies, prompting the need for an upgraded solution.

Our Approach

Our team provided a complete turnkey solution, which included:

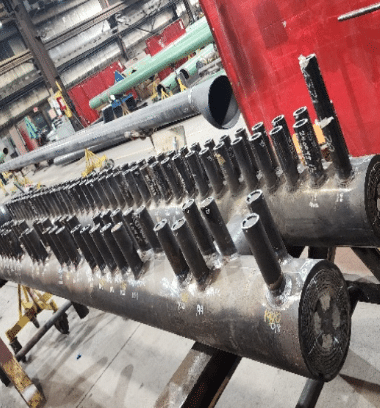

- Engineering design of new RH1 coil bundles featuring in-line, parallel header configuration at the same elevation

- Jumper pipes connecting lower headers

- Straight fin tubes into headers to eliminate the issues caused by bent tubes

- Material optimization: All coils were redesigned in Grade 22 material to reduce costs, enabled by the prior removal of the units’ burner equipment

- Shop-installed thermocouples (TCs) on upper headers and tubes to enhance operational temperature monitoring

We also supplied all materials (four RH1 coils) and managed:

- Field removal and installation of the coil bundles

- Replacement of penetration seals associated with the bundles

Challenges & Results

The project presented several logistical and engineering complexities:

- Tight outage window: All work had to be completed during a limited maintenance period.

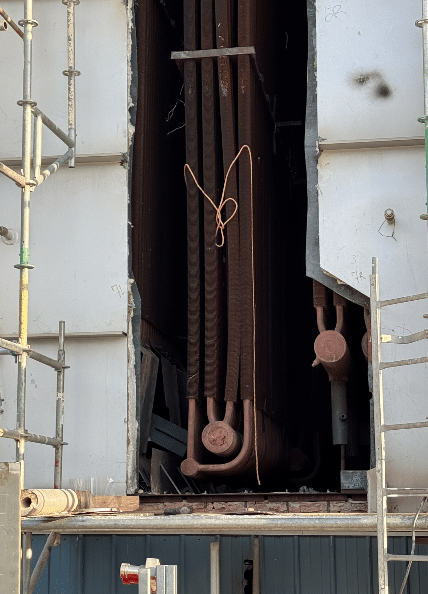

- Access constraints: Both the old and new bundles had to be removed and installed through the sidewall casing of the HRSG.

- Custom trolley system: Nooter Eriksen designed a top-supported trolley system for safe and efficient coil handling.

- Obstructed path: On one HRSG, the coils had to be maneuvered over a catwalk connecting the two HRSGs, requiring precise rigging and handling.

The project delivered measurable benefits for the customer, including enhanced reliability, cost savings, improved monitoring, and on-time completion:

- Reduced downtime: The new RH1 lower header design significantly improved reliability and minimized risk of future failures.

- Cost savings: The material change to Grade 22 delivered immediate cost reductions without compromising performance.

- Enhanced monitoring: Integrated thermocouples provide the plant with valuable operational data to proactively manage system performance.

- On-time completion: The project was successfully delivered within the outage window through proactive collaboration, coordination, and adaptive planning.

Partner With Us!

Our Aftermarket Engineering Team is ready to support your next outage or upgrade.