Executive Summary

As power producers transition to lower-carbon fuels, hydrogen blending has emerged as a practical, near-term strategy to reduce greenhouse gas emissions in natural gas-fired power plants. Gas turbines capable of co-firing hydrogen with natural gas are already in operation, with OEMs planning for blends of up to 50% or even 100% hydrogen by volume in the coming years. While this development is critical for decarbonization, it presents new operational challenges for the Heat Recovery Steam Generator (HRSG).

At Nooter Eriksen (NE), we are actively analyzing and addressing the impacts of hydrogen blending on HRSGs across our global fleet. This paper outlines the technical considerations and potential consequences of hydrogen co-firing on HRSG design, operation, and long-term integrity.

Hydrogen’s Role in Decarbonizing Power

The global push toward net-zero emissions is reshaping the energy landscape. In the power sector, hydrogen offers a pathway to decarbonize existing infrastructure without complete asset replacement. By blending hydrogen into natural gas—typically in increments from 5% to 30% by volume—utilities can lower carbon intensity while using existing gas turbines and pipelines.

However, hydrogen combustion produces a hotter, more reactive flame than natural gas, which directly influences downstream equipment, especially the HRSG.

How Hydrogen Changes HRSG Operation

Hotter Flames, Higher Heat Flux

Hydrogen burns hotter and faster than natural gas, increasing flame temperature and modifying heat transfer profiles in the gas path. This results in:

- Elevated gas-side temperatures entering the HRSG, especially during partial or full-load operation

- Localized heat flux increases in the high-pressure superheater and reheater sections

- Increased thermal stress on headers, tubes, and pressure part welds

The analysis of combustion cases with 20–30% hydrogen blend shows up to 5–10% higher inlet temperatures at the HRSG compared to baseline natural gas firing.

More Moisture, New Corrosion Risks

Hydrogen combustion produces more water vapor per unit of energy, which:

- Raises the acid dew point, potentially impacting low-temperature economizer and stack regions

- Increases the risk of corrosion in areas with cold surfaces or poor drainage

- Shifts energy absorption further downstream into the HRSG, altering the performance of cold-end components and increasing condensation-related corrosion risks

Critical Risks for HRSG Systems

Material Choices for Longer Life

The combination of increased temperature and rapid transients can exacerbate creep and fatigue damage. Owners should:

- Re-evaluate design margins in high-heat-flux sections

- Conduct life assessment studies based on projected hydrogen blend scenarios

- Consider upgrading to advanced materials such as T91, austenitic steels, or duplex alloys that provide greater resistance to temperature and corrosion under hydrogen-rich conditions

Managing FAC in a Hydrogen Environment

With higher water vapor content and potential condensate formation, FAC in low-pressure circuits may accelerate. Key actions include:

- Monitoring chemistry controls and oxygen scavenger performance

- Inspecting elbows, tees, and risers in LP and IP systems

- Assessing temperature profiles and material compatibility to ensure sufficient protective oxide formation in vulnerable regions

Redesigning Burners & Ducts for H₂

The use of hydrogen—either in the combustion turbine (CT) or in the duct burner—alters exhaust temperature, flow composition, and moisture content, all of which affect downstream HRSG performance.

When hydrogen is introduced into the gas turbine, it changes the combustion characteristics and exhaust gas composition, increasing the amount of water vapor and reducing CO₂ per unit of energy. This shift affects both the heat transfer behavior and the fluid dynamics within the HRSG.

When hydrogen is introduced into duct burners, flame characteristics such as shape, length, and stability may shift due to hydrogen’s high flame speed and diffusivity. This can result in altered flame impingement zones and increased duct wall and liner temperatures. The higher adiabatic flame temperature and faster reaction kinetics of hydrogen may lead to more localized heat input, requiring careful redesign of duct burner tips and flame stabilization devices.

Additional considerations include whether burner tips, fuel lances, or atomizing air systems must be redesigned to accommodate hydrogen’s properties. Hydrogen’s lower volumetric energy density (about one-third that of natural gas) means larger flow volumes are required to achieve the same heat input. This often necessitates resizing nozzles, upgrading fuel skids, or incorporating larger fans to deliver higher flowrates—particularly for systems using pre-mixed or staged combustion burners. These modifications could impact burner skid size, layout, and even available space within the duct.

These combustion changes can affect:

- Flow distribution into the HRSG, particularly near catalyst beds and transition duct zones

- Flame impingement zones, especially where baffles or diverter vanes are installed

- SCR performance, due to shifted temperature windows and ammonia slip patterns

Nooter Eriksen’s Hydrogen Solutions

Modeling Performance for H₂ Blends

- High-fidelity CFD simulations with blended-fuel combustion profiles

- Tube temperature mapping and fatigue life predictions

- Steam cycle impact modeling that considers changes to both exhaust gas temperature and composition, allowing for better prediction of HRSG heat rates and steam flow behavior

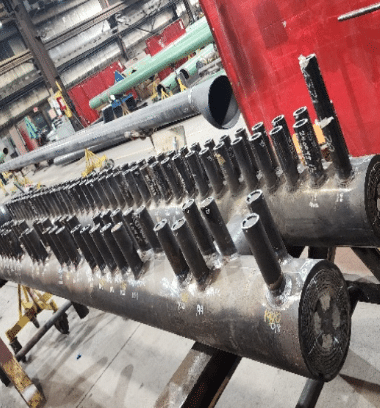

Updating Designs for Hydrogen Resilience

- Updated design criteria for pressure parts exposed to higher temperatures

- Evaluation of tube metallurgy options for future-proofing retrofit projects

- Review of volumetric flow and density changes in steam and water-side systems to accommodate altered heat transfer rates under hydrogen-rich firing conditions

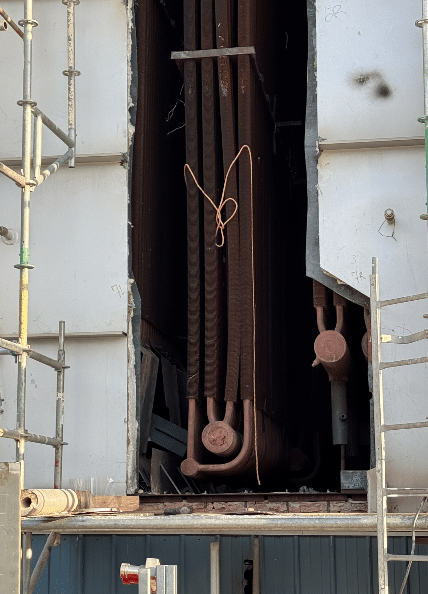

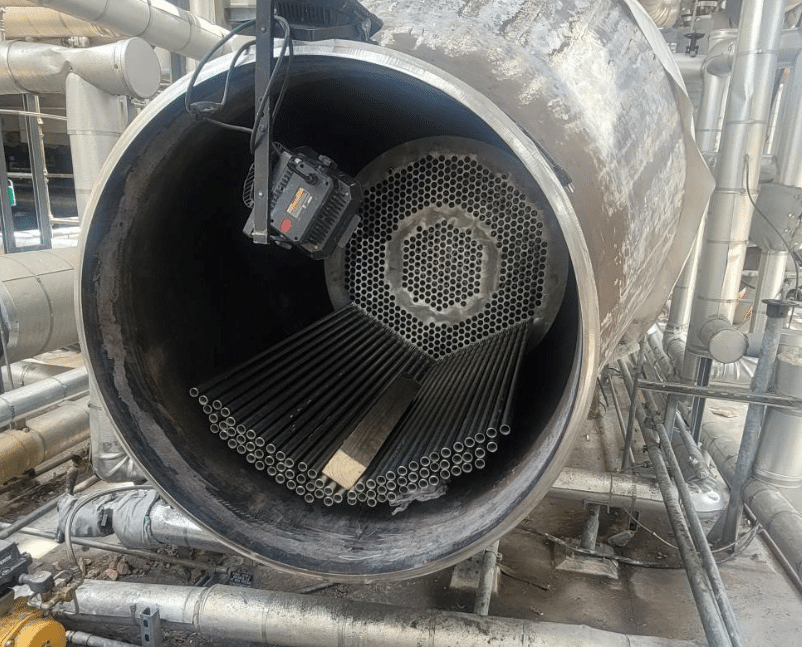

Targeted Inspections & Upgrades

- Targeted inspection programs for high-risk headers and tubes

- Addition of online temperature monitoring in high-heat-flux zones

- Design and supply of replacement coils, baffles, and liners optimized for H₂ blends

Preparing Your HRSG for the Hydrogen Future

As hydrogen blending continues to gain momentum, HRSG owners will face growing pressure to adapt. Whether for pilot testing or permanent integration, Nooter Eriksen is uniquely positioned to support plant teams through this transition—with field-proven engineering, inspection, and upgrade solutions. Our approach ensures thermal performance, reliability, and lifecycle integrity—even as fuel compositions evolve.