Home | Cooling Towers

Cooling Towers

Our cooling tower range includes both Mechanical and Natural Draft Cooling Towers. Our engineers tailor component combinations to deliver cost-effective systems that meet performance requirements. We offer cooling towers constructed from concrete, pultruded composites, wood, and steel, depending on project needs.

Mechanical Draft Cooling Towers

Our mechanical draft cooling towers are designed to efficiently cool hot water across various industries, including power generation, oil and gas, chemical processing, steel production, and food manufacturing.

These towers are classified as induced or forced draft, based on fan positioning, and as counterflow or crossflow, based on fill arrangement.

Constructed from pultruded FRP (Fiber Reinforced Polyester), our towers are ideal for long-term use in corrosive environments. Designed to CTI STD-137 and CTI STD-152 standards, they offer exceptional durability and performance.

Hybrid Cooling Towers

Hybrid Cooling Towers integrate wet evaporative cooling with dry heat exchangers to reduce visible plume emissions and comply with environmental regulations.

Plume Abatement

Our hybrid Cooling Towers combine air-cooled and water-cooled technologies to effectively reduce visible plume emissions. By dynamically switching between evaporative or hybrid modes, our systems ensure environmental compliance and operational efficiency.

Advantages of Hybrid Cooling Solutions

- Energy Efficiency: Hybrid systems adapt to ambient conditions, using air cooling during cooler periods and water cooling during peak heat, optimising energy and water usage.

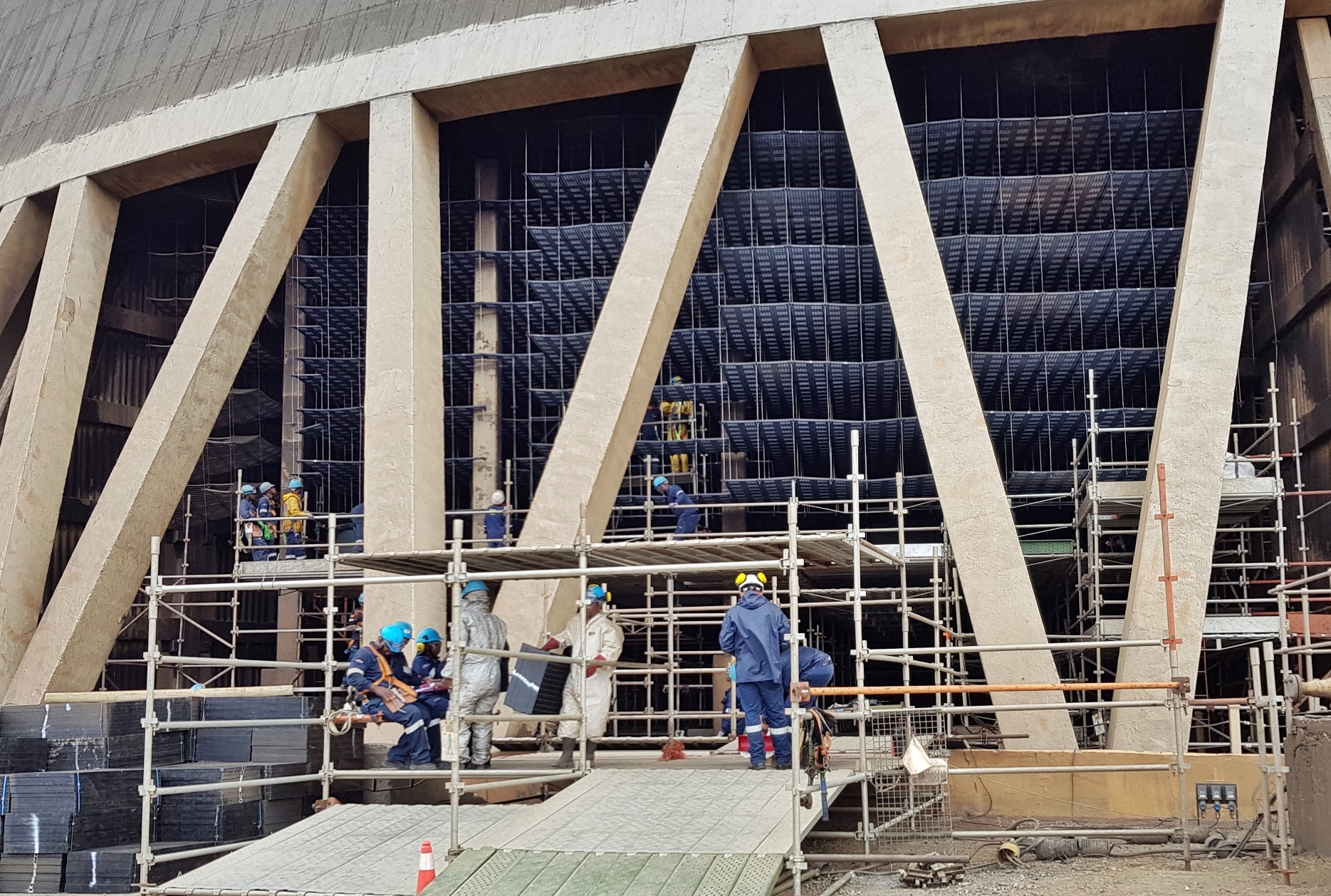

Natural Draft Cooling Towers

NEXT specialises in the design and supply of Natural Draft Cooling Towers, particularly suited for large-scale thermal and nuclear power facilities where substantial volumes of heated water require cooling.

Thanks to their hyperbolic structure, these towers utilise the natural upward movement of air to cool water without the need for mechanical fans, significantly reducing operational costs. Where spatial constraints exist, performance can be enhanced through the integration of auxiliary fans.

Constructed from cast-in-situ concrete, our towers are engineered for longevity, even in the most demanding environments. Our extensive global portfolio spans multiple industries and geographies.

Bulk Air Cooling Towers

Bulk Air Coolers (BACs) are critical infrastructure in deep-level mining environments, designed to mitigate extreme underground temperatures and ensure safe, productive working conditions. BACs can be either surface-mounted or installed underground, with the primary function being to reduce the temperature of ventilation air in underground mine workings.

Surface BAC’s are typically multicell configurations tailored to site-specific airflow’s and thermal load requirements. Underground BAC’s are usually constructed within the mine workings and in tunnels specifically for this purpose.

Our BACs can be constructed from various materials, including Reinforced Concrete or from pultruded FRP (Fiber Reinforced Polyester). Our BACs are ideal for long-term use in harsh environments and offer exceptional durability and performance.

NEXT offers BACs in either forced or induced draft, as well as in either a packed (Film, Trickle, or Splash Pack) counterflow or cross flow (Packed or spray type) configuration.

Slurry and Solution Cooling Towers

Our engineers have developed a field-erected cooling tower specifically designed for slurries and highly abrasive or corrosive solutions.

Key features include:

- Forced draught fans

- Removable spray lances, accessible from external walkways

- Fill-less design, ideal for applications prone to internal fouling

Drift eliminators are assembled into easily removable pads and can be equipped with an automatic CIP (Cleaning in Place) system. Drift losses are minimised to as low as 0.002% of the recirculating flow rate. These towers can be constructed in various materials to suit environmental or project-specific requirements.

More Solutions

Cooling Towers

Mechanical Draft, Natural Draft, Hybrid

Air Cooled Condensers

Forced Draft A-Frame

Aftermarket

Refurbishment, Upgrades, Spare Parts