Home | Aftermarket Services

Aftermarket Services

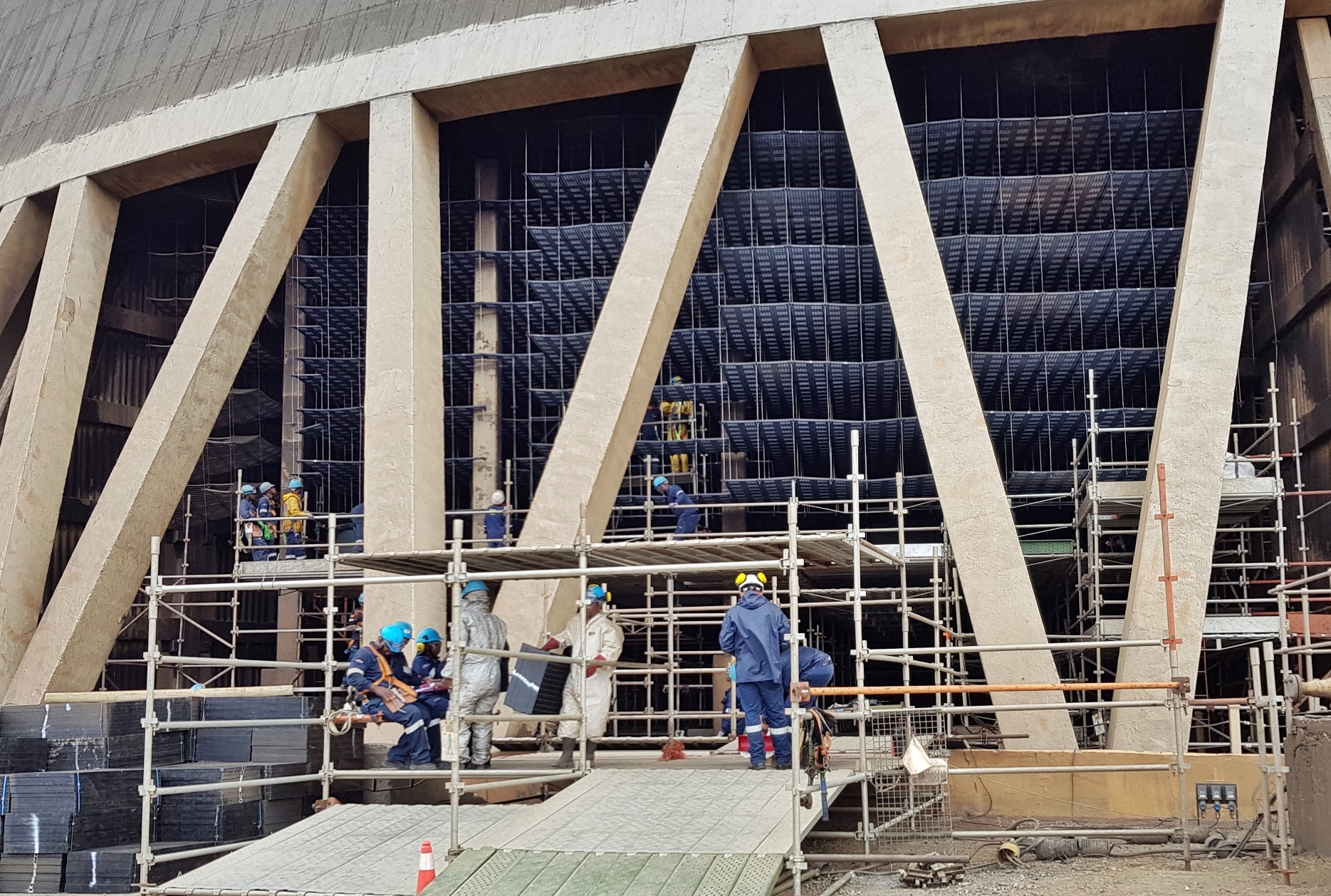

NEXT sets the global benchmark for refurbishment and aftermarket solutions, encompassing the installation of fill media, drift eliminators, spray systems, nozzles, and fan mechanical components.

Our commitment goes far beyond initial system commissioning — we deliver end-to-end post‑installation support to maximise performance, efficiency, and reliability.

We help you:

- Restore original operating conditions

- Enhance system performance

- Optimise energy consumption

Our tailored maintenance strategies are backed by the expertise of our engineering and R&D teams.

Our specialists are available to assess your cooling system.

Our service approach is delivered in two phases: the first — common to all our product lines — is essential to identify intervention areas based on your requirements, current system conditions, plant configuration, and environmental factors.

We offer:

- Immediate technical support

- Performance data analysis

- Computational Fluid Dynamics (CFD)

- On‑site inspections

- Feasibility studies

The results of these activities form the basis for jointly defining targeted interventions, ensuring clear timelines and cost control.

Cooling Towers

Replacement and modernisation of internal components:

- Maintenance / Upgrades of fans, gearboxes, and motors

- Servicing of hybrid (WET/DRY) cooling tower systems

- Installation of noise‑reduction equipment:

- Anti‑Legionella system design and implementation

- Fire prevention solutions

- Louver installation

Air‑Cooled Condensers

Intensive ACC cleaning

- Helium leak test and repairs

- Vacuum decay testing and vacuum system restoration

- Re‑bundling

- Maintenance / Upgrades of fans, gearboxes, and motors

- Parallel Condensing (PAC) system

- Wind‑dependency reduction measures

More Solutions

Cooling Towers

Mechanical Draft, Natural Draft, Hybrid

Air Cooled Condensers

Forced Draft A-Frame

Aftermarket

Refurbishment, Upgrades, Spare Parts