Home | Air Cooled Condensers

Air Cooled Condensers

Efficient. Sustainable. Built to Perform.

Our design is in line with industry standards and engineering practices, as well as international codes (HEI code):

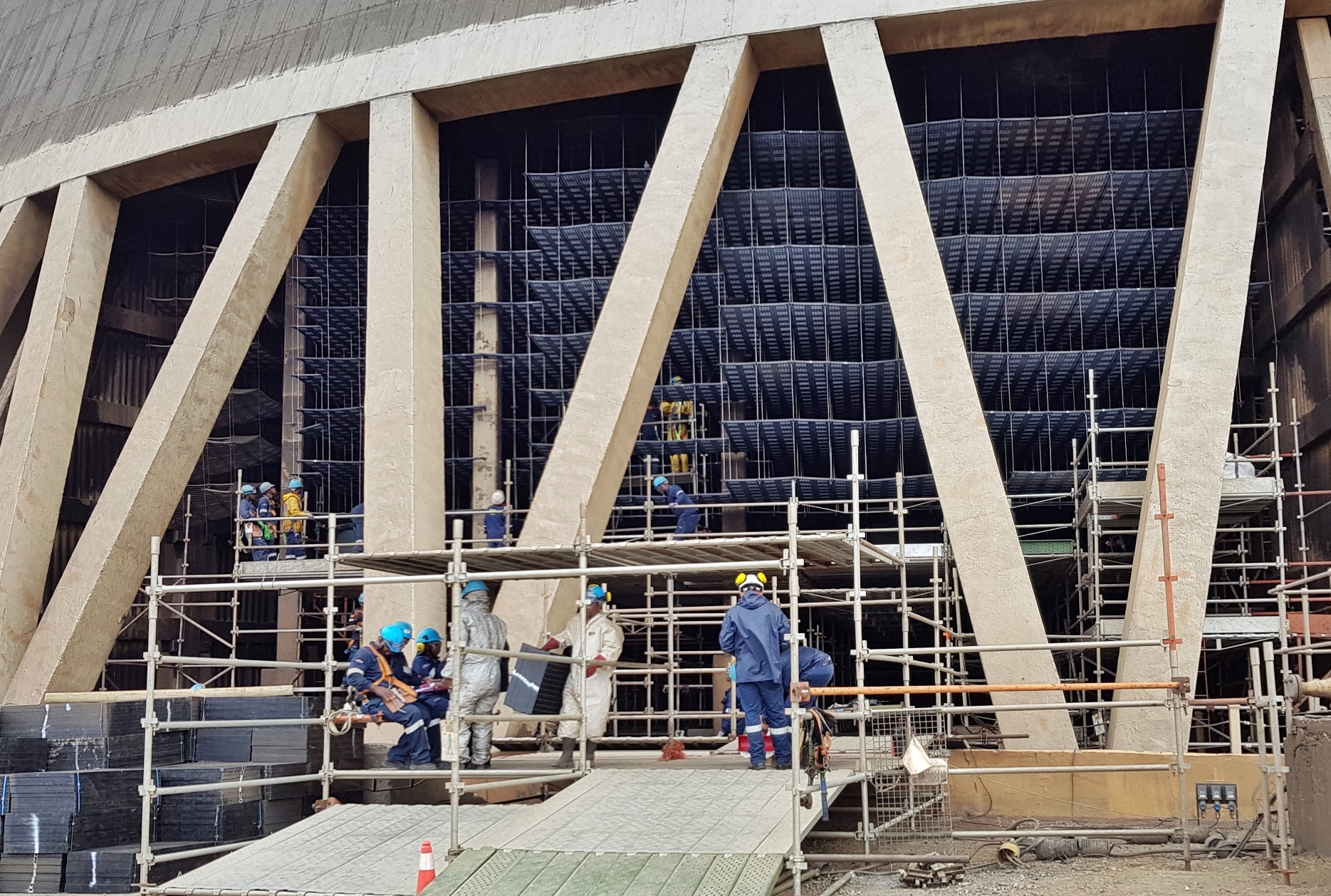

A-Frame Design

Smart Design for Direct Steam Condensation

Our A-frame condensers feature a triangular structure that minimizes steam ducting. This allows direct condensation of turbine exhaust without intermediate systems—returning condensate straight to the boiler with zero water loss.

Design Highlights

- Modular Construction: Easy to install, maintain with minimal downtime.

- FV to 1.5 bar(a): maximize steam turbine output

- Heavy-Duty Materials: Galvanized steel, Aluminium cladded tubes, and UV-resistant FRP offer decades of service.

- Robust Structure: Engineered for wind, seismic, and snow loads typical in all regions.

- Forced Draft: mechanical group is protected and exposed to fresh air

- Maintenance Made Easy: Crews can reach all critical areas, handling components.

Feedback from operators underscores that A-frame ACCs often outlast expectations, with routine annual inspections sufficient for long-term reliability.

Single Tube Row Configuration

Compact. Efficient. Freeze-Resistant.

Our air-cooled condensers are designed with single row tube-bundles, providing maximum thermal efficiency in all climates. They uniquely optimize heat transfer and airflow while maintaining compact footprints and low operating noise.

Single-row overperform conventional multi-row models, especially at low ambient temperatures or fluctuating loads. This proven technology has transformed dry cooling worldwide, especially for renewable energy projects and power generation

Our single row tube-bundle design features:

- low pressure drops (steam and air side)->Lower energy use

- even steam distribution

- No “dead zones” or freezing risks

- Nearly 100% finned surface for optimal heat transfer

- Allows high steam velocity and efficient drainage

- Steam-contact design keeps condensate at safe temperatures

- Corrosion-resistant aluminum cladding

Operating Under Vacuum

Maintaining Performance in Low-Pressure Conditions

ACCs run under vacuum. Small air leaks and non-condensable gases are inevitable—but must be continuously removed to preserve thermal efficiency (Holding). Rapid initial evacuation (Hogging) is critical for modern power plant with increasing demand flexibility . High-capacity Vacuum systems like steam jet ejectors (SJAE) or Liquid Ring Pumps (LRVP) ensure proper operability

Tailored Solutions

Custom Designs for Unique Site Needs

Every site is different. We offer bespoke ACC systems to meet your specific operational and environmental requirements.

Noise Control

We tackle noise from fans, motors, and steam ducts with:

- Low-noise and ultra-low noise fan blade shapes

- Soundproof mechanical group enclosures

- Insulated duct surfaces

- Inlet/outlet silencers for maximum reduction

Cold Climate Adaptations

Reliable Performance in Freezing Conditions

- Thermal insulation and Heat tracing

- Fan control systems and logics

- Steam Isolation valves

- Optimized dephlagmator bundles configuration up to Full dephlagmation

- Hot-box configuration

More Solutions

Cooling Towers

Mechanical Draft, Natural Draft, Hybrid

Air Cooled Condensers

Forced Draft A-Frame

Aftermarket

Refurbishment, Upgrades, Spare Parts