Additional Services

Wyatt Field Service Company is a top heavy mechanical contractor, providing leading-edge services for the petroleum refining and petrochemical industries.

As the industry’s premier nationwide heavy mechanical contractor, Wyatt listens continually to our customers and adds additional services to meet their ever evolving needs. We continue to expand our services as we strive to become the “Complete Package” for our customers.

Wyatt Field Service Refractory Division collaborates closely with plant owners, process engineers and other contractors to ensure linings are installed in place following design specifications designated by the customers to perform projects safely and efficiently with high regards to safety and economical impact to customers.

Wyatt Field Service Refractory Division collaborates closely with plant owners, process engineers and other contractors to ensure linings are installed in place following design specifications designated by the customers to perform projects safely and efficiently with high regards to safety and economical impact to customers.

Capabilities

- Project Management

- Scheduling

- Daily Cost Tracking

- Estimating (P6, AutoCAD)

- Quality Assurance & Quality Control Inspection Staffing

- API 936 Refractory Personnel Certification Program

- Recommended Repair Procedures

- Digital Reporting

- Refractory Demolition

- Hydro Demolition

- Riser Lines

- Spent Cat Lines

- Overhead Lines

- Regen Walls

- Reactor Walls

- Coker Pits

- Fireproofing

- Coatings Removal

- Sulphur Pits

- Drums

- Pump Pads

- Foundation

- Hydro Demolition

- Chemical Resistant Linings

- Acid Resistant Brick and Tile

- Epoxy

- Material Supply

- All Types of Refractory Materials

- All Types of Corrosion Resistant Materials

- Field Services

- Silicon Stud Welding (RAW)

- Anchor Welding of all types

- Brick Installation

- Acid Brick

- Arches & Domes

- IFB

- Hard brick

- Gunite Installation

- Conventional

- Wet Gunning/ Shotcrete

- Intumescent & Cementitious Fireproofing

- Plastics & Other Rammable

- Ceramic Fiber Installation

- Blanket

- Modules

- Z-Block

- Vacuum form

- Vibration casting Installation

- Pump casting Installation

- Shop Services

- Pre-Cast Shapes

- Vibration-Cast Pipe Linings

- Vessel Lining

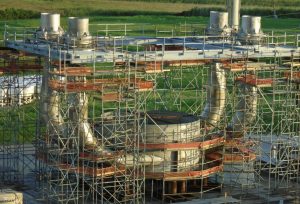

Wyatt Field Service has assembled a team of highly qualified Scaffold experts that have outperformed time and time again in the field. Offering a modernized tube and clamp system for all industrial project needs with the supervision and craft available to perform daily in and out to meet goals and maintain the highest level of safety, reliability and productivity on site.

Capabilities

- Scaffolding Service

- Project Management

- Scheduling

- Scaffold Engineering & Design

- Scaffold Erecting & Modification

- Scaffold Inspections

- Avontus Scaffold Designing

- Variety of Scaffolding

- Pinlock System (Layher Style)

- Tube & Clamp

- Engineered Scaffolding to Support Structures

Wyatt’s Exchanger Service has added the complete package, as it relates to field servicing of Heat Exchangers. Our experienced crews along with the latest equipment gives Wyatt the competitive edge for all your Heat exchanger maintenance needs. Our primary goal is to execute the job safely. We will take it all the way from expediting, to handling any Demo and New installation, any Push/Pull arrangement, including jobs that required heavy rigging and complex extractions involving our in-house Engineering.

BUNDLE EXTRACTION FLEET

(4) – Aerial Extractors (2) – Self Propelled Extractors

(3) 45 Ton & (1) 25 Ton Max. Capacity – 50,000#

Max. Capacity – 90,000# Max. Bundle Length – 29 ft.

Max. Bundle Length – 36 ft. Max. Bundle Diameter – 6’-6”

Max. Bundle Diameter – 9’-10” Max Working Height – 20 ft.

(6) – Bundle Dollies

Max. Capacity – 36,000#

WYATT/DELTA FLEET & CAPACITIES

- (1) Qty. 23-Ton Truck Mounts:

Max Capacity = 6’ Dia. Tubesheet x 22’ overall length - (4) Qty. 30-Ton Aerials:

Max Capacity = 6’ Dia. Tubesheet x 22’ overall length - (1) Qty. 60 Ton Aerials:

Max Capacity = 6’ Dia. Tubesheet x 22’ overall length - (2) Qty. Self Propelled:

Max Capacity = 9’9” Tubesheet x 40’ overall length - (6) Qty. Bundle Dollies:

Max Capacity = 6’ Dia. Tubesheet x 22’ overall length

Torqueing and Stud Removal

- Hydraulic torque wrenches

- All stud sizes

- Heavy hex sizes

- Socket and low clearance link

- Nut splitting

- Stud removal services

Note: Wyatt utilizes the use of rental tensioning equipment

Wyatt welders are ASME certified and experienced to perform work on all types of metallurgy from Carbon Steel to exotic alloys.

Wyatt have over 4000 Weld Procedures with Welding Engineers who qualify our welders to meet the needs of our customers

We are qualified to perform work to the following codes: ASME (U, U2, AND S) National Board, AWWA, API, and ANSI.

- Multiple GMAW/FCAW WPS/PQRs qualified with various alloys – including Inconel, Stainless, Hastelloy, and others.

- Multiple GTAW WPS/PQRs qualified with various alloys including Inconel, Stainless, Chrome, and others.

- Available 24/7 – 365 Days/Year

- NSS/WYATT shared resources i.e. QA/QC, Safety Supervisors, Confined Space Attendant, Fire Watch – Cost savings to customer

FIELD MACHINING CAPABILITIES

Pipe Cutting and Beveling

- Any wall thickness from 1-1/2” to 48” sizes in Trailer 6” to 24”

- Carbon, stainless steel, chrome, P91, exotic alloys

- Counter boring, taper boring, schedule reduction

- Standard, compound and J bevels as well as special configurations

- Valves, elbows, tees and other components

- Minimal radial and axial clearance needed

Boring

- Hole boring in headers for weld-o-lets and tube stubs

- Boring of nozzles in vessels

- Buckets, loaders and other articulated equipment

Flange-facing

- Portable O.D. and I.D. mount machines

- Sizes from 1-1/2” to 102”

- Sizes on Trailer 5” to 48”

- All types: flat, raised face, RTJ and clamp-type flanges

Milling

- Exchange partition

- Keyways in shafts

- Access doors on Surface Condensors

- Pump Bases

Laser Scanning/3D

Wyatt uses dimensional control survey services to reduce risk and solve challenges faced by engineering/design, fabrication, construction and installation process.

We Use a Leica Total Station and a Faro Scanner.

Typical work scope:

- Dimensional capture of existing elements

- Capture temperature data as required for adjustment from thermally expanded to fabrication dimensions (as built)

- Model elements as required for as-built condition prior to dimensional check

- Detail design check, correcting any dimensional errors and eliminating any leave-long field fits in the design package

- Dimensional capture of fabricated elements for comparison to the corrected design documents and trial fitting in the model created in step three

- Construction field support: Lay-out and check of foundations, cut-lines, tie-ins of all other elements as required for fit-up

- Redesign of pipe spools, as required, to compensate for the “dimensional drift” associated with shop tolerances and dimensional errors in fabrication and construction layout

Items we typically check:

– Equipment validation

– Design verification

– Piping spool validation

– Plant facilities verification of pre-design interference checking

– Deformation survey

Software we utilize:

AutoCAD

AutoCAD Plant 3D

LFM (to work with scan data)

Recap (to work with scan data)

Cyclone (to register scan data)

Scene (to register scan data)

Navisworks

Insulation Services

Our capabilities as an established group of Insulation Management and Supervision will gladly facilitate any and all insulation needs. From supply and fabrication of hot and cold applications to installation and inspection of insulation projects. Available for wide variety of units including Process Pipes, Boilers, Towers, Tanks, Coke Drums, Heaters and Valves. Embracing safety as our main focus, minimizing efficiency loss, corrosion and costly repairs.

Capabilities

– Insulation Service

– Project Management

– Scheduling

– Installation of Materials

– Capital, New Construction and Planned Outages

– Facility Managed Maintenance Programs

– Acoustic, Cryogenic and Heat Conservation Systems

– Design & Fabrication of Removable Insulation Blankets

– Aerogel Flexible Blankets

– Standing Seam Panels for Coke Drums and Tanks

– Hot and Cold Application & Protection for Personnel and Equipment

– Calcium Silicate Pipe and Block Products

– Off-Site Shop Facilities