Understanding the Basics of a Mechanical Turnaround

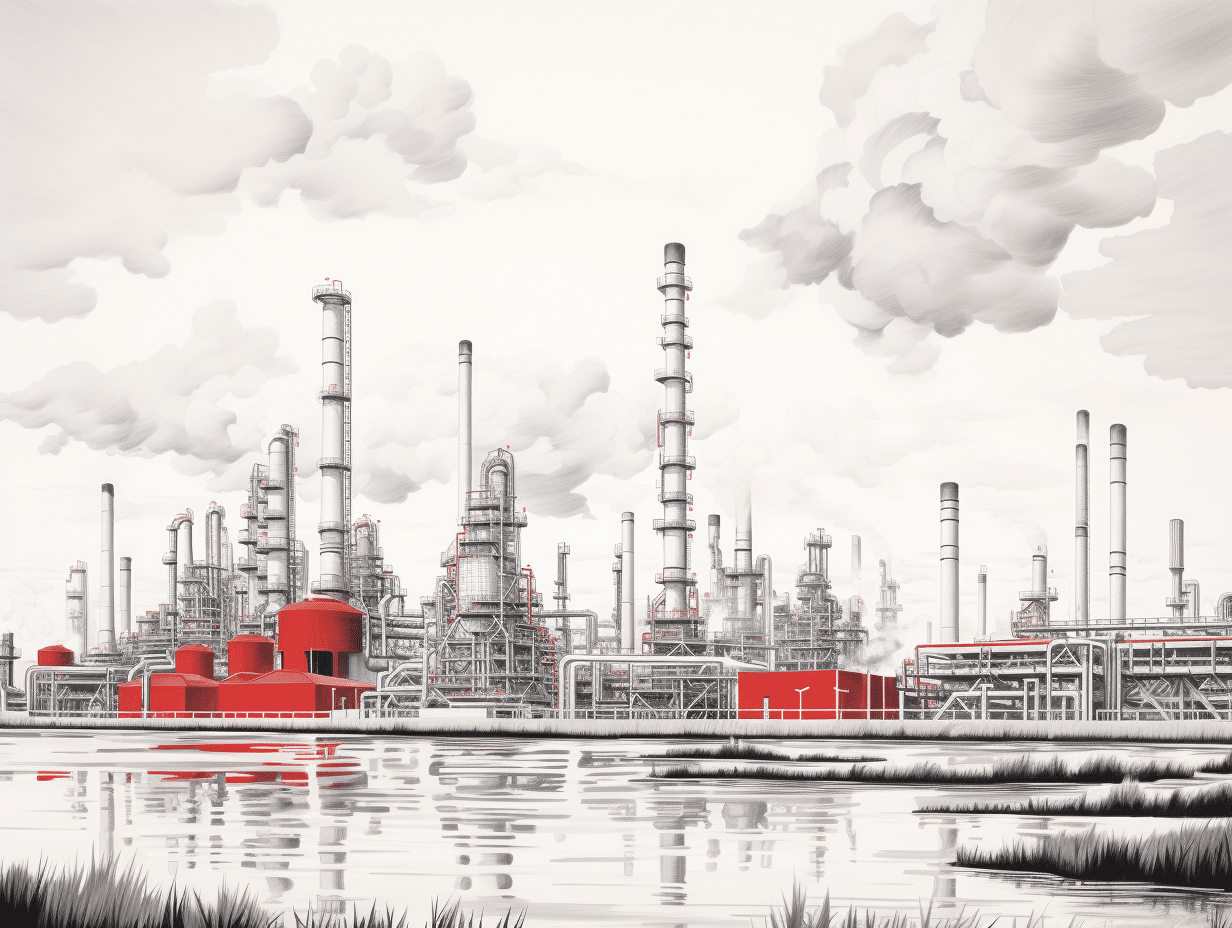

In the world of Oil and Gas, there’s a vital process known as Mechanical Turnarounds. These operations ensure equipment runs smoothly and safely. Whether you’re a seasoned professional or just interested in the topic, this blog will break down the essentials of mechanical turnarounds, making them easy to understand. We’ll explore their significance, phases, and safety measures.

Join us as we demystify the basics of Mechanical Turnarounds in Oil and Gas.

What is a Mechanical Turnaround?

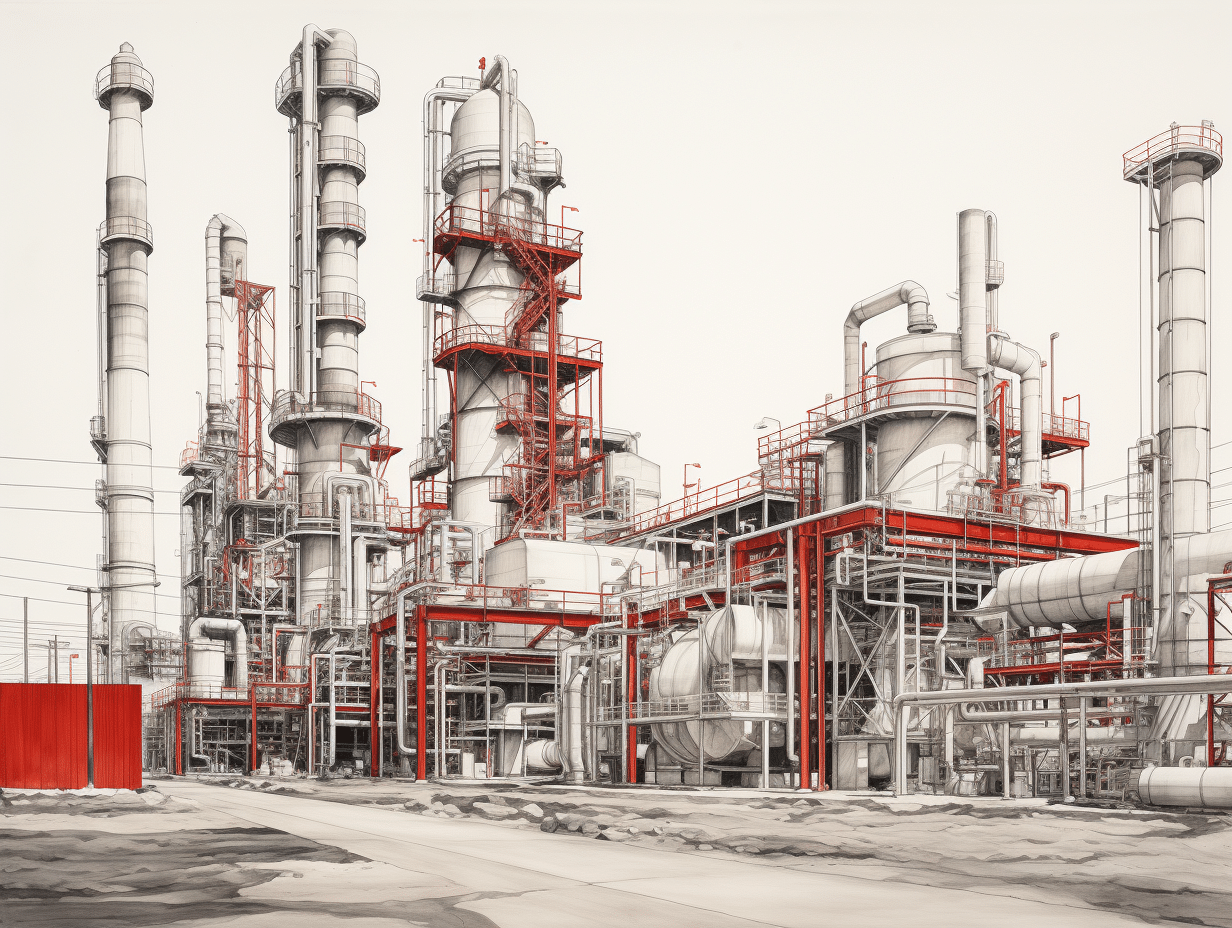

In the complex landscape of the Oil and Gas industry, a Mechanical Turnaround stands as a cornerstone process that plays a pivotal role in maintaining operational efficiency and safety. But what exactly is it?

A Mechanical Turnaround is a meticulously planned and executed operation during which a facility or part of it is temporarily shut down to undergo comprehensive maintenance, inspection, and necessary repairs. This downtime allows for the critical examination and servicing of equipment, pipelines, and infrastructure that are essential to the production and safety of an oil or gas facility.

Why Mechanical Turnarounds Matter

Now, you might be wondering why these turnarounds are so significant.

Here’s the crux of it:

- Asset Optimization: Maximize equipment efficiency and longevity.

- Safety Assurance: Identify and address issues for safety and environmental compliance.

- Compliance: Meet regulatory obligations through periodic maintenance.

- Cost Efficiency: Save on long-term costs by preventing breakdowns and minimizing downtime.

In essence, a Mechanical Turnaround is the industry’s way of ensuring that its operations run smoothly and safely, and it’s a practice deeply rooted in the pursuit of excellence and responsibility within the Oil and Gas sector.

Key Phases of a Mechanical Turnaround

Mechanical Turnarounds are intricate processes that involve several carefully planned phases. Each phase is essential to ensure that the turnaround is executed efficiently and effectively.

Let’s break down these key phases:

1. Planning and Scheduling

The first and arguably the most critical phase of a Mechanical Turnaround is the planning and scheduling stage.

Here, meticulous planning takes place, involving:

- Scope Definition: Identifying the scope of work, which includes what equipment needs maintenance or repair.

- Resource Allocation: Determining the necessary resources, including labor, equipment, and materials.

- Timelines: Establishing a detailed timeline for each activity, ensuring minimal downtime.

- Budgeting: Allocating funds and preparing a budget for the entire turnaround.

2. Shutdown and Isolation

Once the planning is complete, the facility is prepared for shutdown.

This phase includes:

- Equipment Shutdown: Safely shutting down equipment and systems, often in a predetermined sequence to avoid complications.

- Isolation: Isolating sections of the facility to ensure the safety of workers and prevent the flow of hazardous materials.

3. Inspection and Assessment

During this phase, a comprehensive inspection and assessment of all relevant equipment and infrastructure is conducted:

- Visual Inspection: Inspecting components for visible signs of wear, damage, or corrosion.

- Non-Destructive Testing (NDT): Using advanced techniques like ultrasound or radiography to detect hidden flaws.

- Data Analysis: Collecting and analyzing data to identify potential issues and determine the extent of maintenance required.

4. Repairs and Maintenance

After identifying necessary repairs and maintenance, this phase involves:

- Corrective Actions: Addressing identified issues, which may include equipment replacement, refurbishment, or repairs.

- Preventive Measures: Implementing measures to prevent future issues and enhance equipment reliability.

5. Testing and Quality Control

Before restarting operations, thorough testing and quality control measures are essential:

- Functional Tests: Ensuring that repaired or replaced equipment functions correctly.

- Safety Checks: Verifying that safety systems are operational.

- Quality Assurance: Conducting quality checks to meet industry standards.

6. Restarting Operations

Finally, the facility is prepared for a safe and efficient restart:

- System Integrity: Ensuring that all systems are functioning as expected.

- Gradual Ramp-Up: Gradually resuming operations to avoid sudden stress on equipment.

- Monitoring: Continuously monitoring equipment performance post-restart.

These are the fundamental phases of a Mechanical Turnaround. Each phase is interconnected and crucial for a successful turnaround.

Importance of Safety in Mechanical Turnarounds

Safety is the cornerstone of Mechanical Turnarounds in the Oil and Gas industry, and for good reasons:

Preserving Lives and the Environment

Safety measures are paramount because they protect both human lives and the environment from potential hazards. The industry’s operations involve complex machinery and hazardous substances, making safety non-negotiable.

Meeting Regulatory Requirements

Strict regulations govern the industry, necessitating adherence to safety standards. Compliance failures can lead to legal repercussions, fines, and facility shutdowns.

Maintaining Reputation and Trust

A strong safety record is a testament to a company’s responsibility and reliability. Conversely, safety lapses can harm a company’s reputation, erode trust, and result in lost business.

Mitigating Financial Risks

Safety investments reduce the risk of costly accidents or unexpected downtime, serving as a preventive measure against financial losses.

Boosting Morale and Productivity

Safe work environments foster high employee morale and productivity by instilling confidence in the workforce.

Driving Continuous Improvement

Safety commitment leads to a culture of constant improvement. Lessons from past incidents inform the enhancement of safety protocols and procedures.

Safety specialists and rigorous safety protocols are vital during Mechanical Turnarounds.

Specialists oversee:

- Safety inspections and audits.

- Worker training on safety procedures.

- Emergency response plans.

- Safety compliance enforcement.

In essence, safety isn’t just a box to tick; it’s an essential investment that pays dividends in human well-being, environmental protection, legal compliance, reputation, and business success.

Challenges With Mechanical Turnarounds

Challenges encountered during Mechanical Turnarounds in the Oil and Gas industry include:

- Budget Constraints: Limited budgets can hinder comprehensive maintenance and repairs, potentially impacting equipment reliability.

- Time Constraints: Time limitations can lead to pressure on turnaround schedules, risking delays and increased costs.

- Skilled Labor Shortage: Finding and retaining skilled labor for specialized tasks can be a significant challenge in the industry.

- Environmental Concerns: Stricter environmental regulations require facilities to adhere to environmentally friendly practices during turnarounds.

- Scope Creep: Expanding the scope of work beyond the original plan can lead to project delays and budget overruns.

- Logistics and Supply Chain Issues: Ensuring timely delivery of equipment and materials can be a logistical challenge during turnarounds.

- Communication and Coordination: Effective communication and coordination among various teams and stakeholders are essential but can be complex.

- Risk Management: Identifying and mitigating risks during a turnaround is crucial to prevent unexpected issues.

Recognizing and proactively addressing these challenges is vital for the successful execution of Mechanical Turnarounds.

Tips for a Successful Mechanical Turnaround

Successful Mechanical Turnarounds in the Oil and Gas industry rely on the following key tips:

- Start Planning Early

- Invest in Training and Development

- Collaborate with Experienced Contractors

- Continuously Monitor Progress

- Prioritize Safety

- Maintain Clear Communication

- Conduct Comprehensive Risk Assessment

- Optimize Resource Allocation

- Embrace Technology

- Learn from Past Turnarounds

- Regularly Update Plans

- Environmental Responsibility

These tips provide a guide to ensure the successful planning and execution of Mechanical Turnarounds, leading to reduced downtime, improved safety, and overall success in the Oil and Gas industry.

Conclusion

Mechanical Turnarounds are crucial in the Oil and Gas industry for ensuring operational efficiency, safety, and regulatory compliance. These processes involve critical stages from planning to restarting operations, each vital for a successful turnaround.

Challenges such as budget constraints and labor shortages can be overcome with early planning, effective communication, and prioritizing safety.

Effectively executed, Mechanical Turnarounds represent strategic investments in the long-term health and safety of Oil and Gas facilities.

Transform Your Turnarounds with WYATT

When it comes to Mechanical Turnarounds in the Oil and Gas industry, success hinges on expertise, innovation, and a commitment to safety. At WYATT, we excel in delivering turnkey solutions that minimize downtime, optimize efficiency, and prioritize safety.

View: Turnarounds Services

Contact us today to discover how our experienced team, cutting-edge technology, and proven track record can elevate your turnaround projects.