Recent Completed Project Examples

NooterEriksen Aftermarket Services can offer complete turn-key services including design, fabrication and installation of replacement or retrofitted components.

Recent Completed Project Examples

Initially Nooter/Eriksen performed a CFD study of the original equipment utilizing field measured exhaust back pressure readings. Once a baseline was established, the new ductwork, diverter and bypass stack were added to the model for evaluation. The new model verified that the replacement equipment would not increase the back pressure during normal operation.

Challenges for the equipment design included utilizing an incomplete set of drawings for the original equipment created in 1971, installing the new equipment on the existing foundations, converting from refractory insulation to blanket insulation with a floating liner system, and using chrome-moly material for the bypass stack in order to avoid installing internal insulation in the stack. To accommodate the duct thermal movements (4) expansion joints were required. In addition to the ductwork, bypass stack, and diverter, Nooter/Eriksen also supplied a guillotine damper, blanking plate, and spring supports for the turbine plenum duct. The ductwork was trial fit at the fabrication facility prior to shipping to the owner’s facility in order to reduce time during field installation.

Nooter/Eriksen was also contracted to provide the field installation of the new equipment.

To ensure an efficient removal and installation, Nooter/Eriksen created a step-by-step narrative including drawings for the entire field scope. The first installation was completed in the spring of 2020 with great success due to the tremendous cooperation between Nooter/Eriksen, the field contractor, and the customer. The final two HRSGs will replaced in early 2021.

The existing equipment performed very well for over 40 years, however there were a couple design flaws that contributed to tube failures and hot casing. During the design stage Nooter/Eriksen developed improved details and modified coils supports to ensure reliable long-term operation.

Additional work was also completed during the outage:

- New coils were chemically cleaned at site

- Exhaust stack was cleaned and recoated while the exterior cladding and insulation were replaced

Nooter/Eriksen provided an entirely new design for both the HP Superheater and Reheater coils. An additional row of HP Superheater was added to provide additional steam flow but also protect the Reheater during high firing operation. The HP Superheater layout was modified to provide additional flexibility to address row to row temperature variation. The upper and lower manifolds for both coils were eliminated in favor of upper and lower headers only with straight tubes. This modification, including a revised layout to the inlet and outlet piping helped improve the flexibility of both the Reheater and HP Superheater systems. Nooter/Eriksen also redesigned the replacement Reheater #2 to Reheater #1 piping with drip pots and condensate detection in accordance with Part PHRSG of ASME Section I including a new ring style desuperheater.

Nooter/Eriksen also provided field technical assistance to oversee the installation of the new valves. The customer wanted to ensure that the work was completed to Nooter/Eriksen’s stringent 9 Cr – 1 Mo requirements.

Replacement Belly Plate Install

Nooter/Eriksen also retrofitted the interconnection piping by manifolding all three HP Superheater #1 outlet connections into a common manifold to utilize a single more reliable attemperator spray valve before splitting back to all three HP Superheater #2 inlet connections. This routing provides for adequate straight pipe length downstream of the attemperator per Nooter/Eriksen’s standards and manufacturer’s recommendations. Using a common manifold provides more even temperature control across the three coils. This design also utilized drip pots with level detection for protection against attemperator overspray or potential leaks.

Nooter/Eriksen also retrofitted the drains to comply with Nooter/Eriksen’s current design standards. The redesign included spring supporting the drain lines to add sufficient flexibility and avoid potential leaks caused by high stress conditions, especially with increased cyclic operation. This design also included condensate detection and pneumatic ball valves to clear any excess water in the drain lines during start-ups or normal operation.

As part of the project, Nooter/Eriksen also designed and supplied 36” x 60” quick access casing doors for both the inlet duct and SCR duct. This is a common upgrade that Nooter/Eriksen has completed at dozens of plants in the past two years. The new access doors are larger than original doors and do not require the use of tools for opening. This allows easier access with equipment and material for future work.

Above Damper

Damper Install

Design challenges included the removal and re-installation of new sections that would interface with the existing main structural elements. There were challenges to incorporate the new section with existing ductwork that had serious deformation.

Nooter/Eriksen also provided the field technical oversight of the customer hired field installation contractor. Nooter/Eriksen supplied field technical advisors for 24 hour per day oversight. The field technical advisor’s close collaboration with the field contractor facilitated the successful project execution.

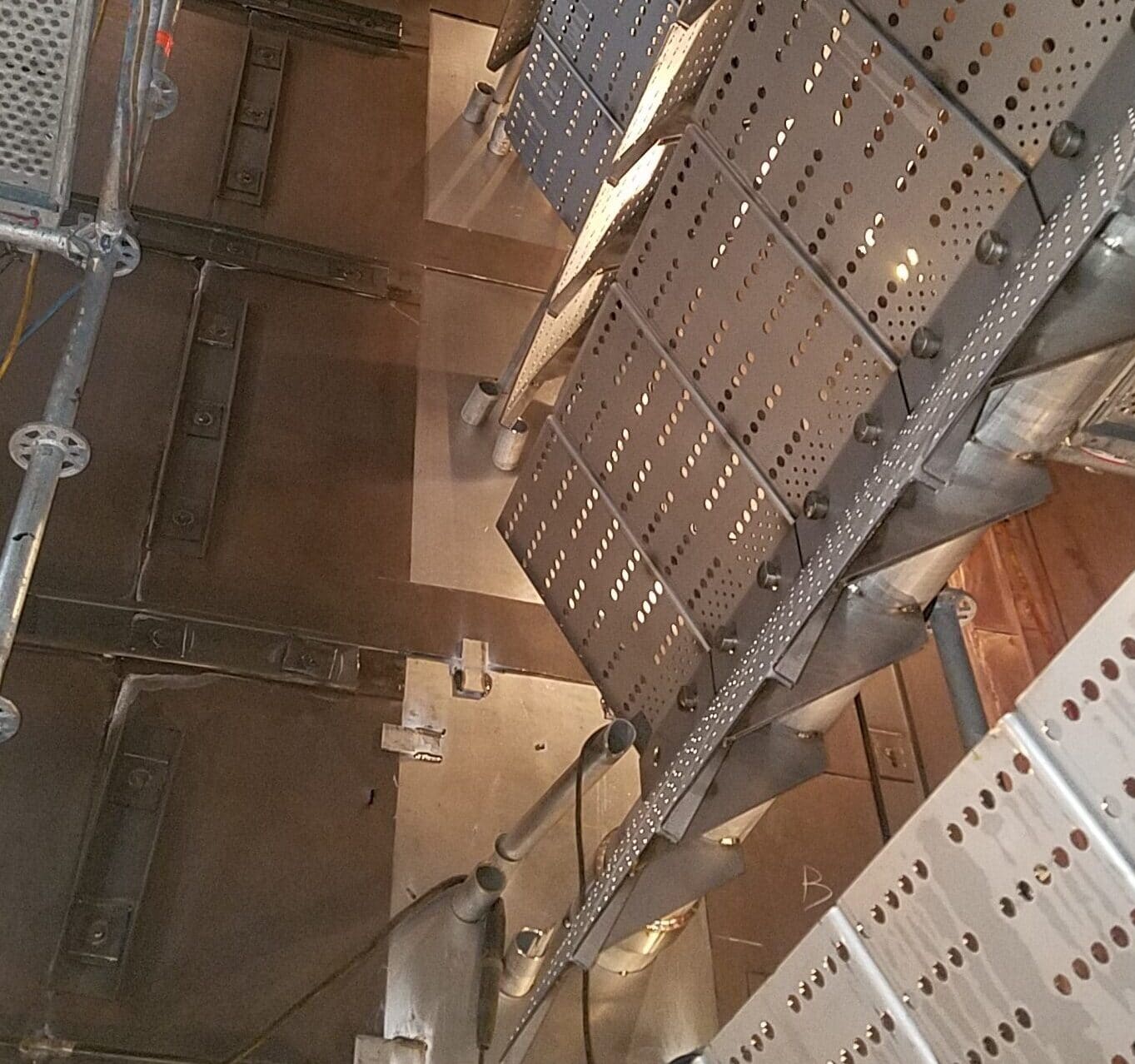

Nooter/Eriksen designed and supplied a more robust liner system for the new turbulent turbine exhaust conditions. The liner details were improved to provide increased strength but also more efficient layout to reduce installation time. The new design included larger diameter pins, reduced pin spacing, thicker liner sections, and an increase in structural components to minimize flexing of the liner system.

Nooter/Eriksen also designed and supplied 24” x 36” quick access casing doors for both the inlet duct and SCR duct. This is a common upgrade that Nooter/Eriksen has completed at dozens of plants. The new access doors are larger than original doors and do not require the use of tools for opening. The new doors allow easier access for equipment, material, and personnel.

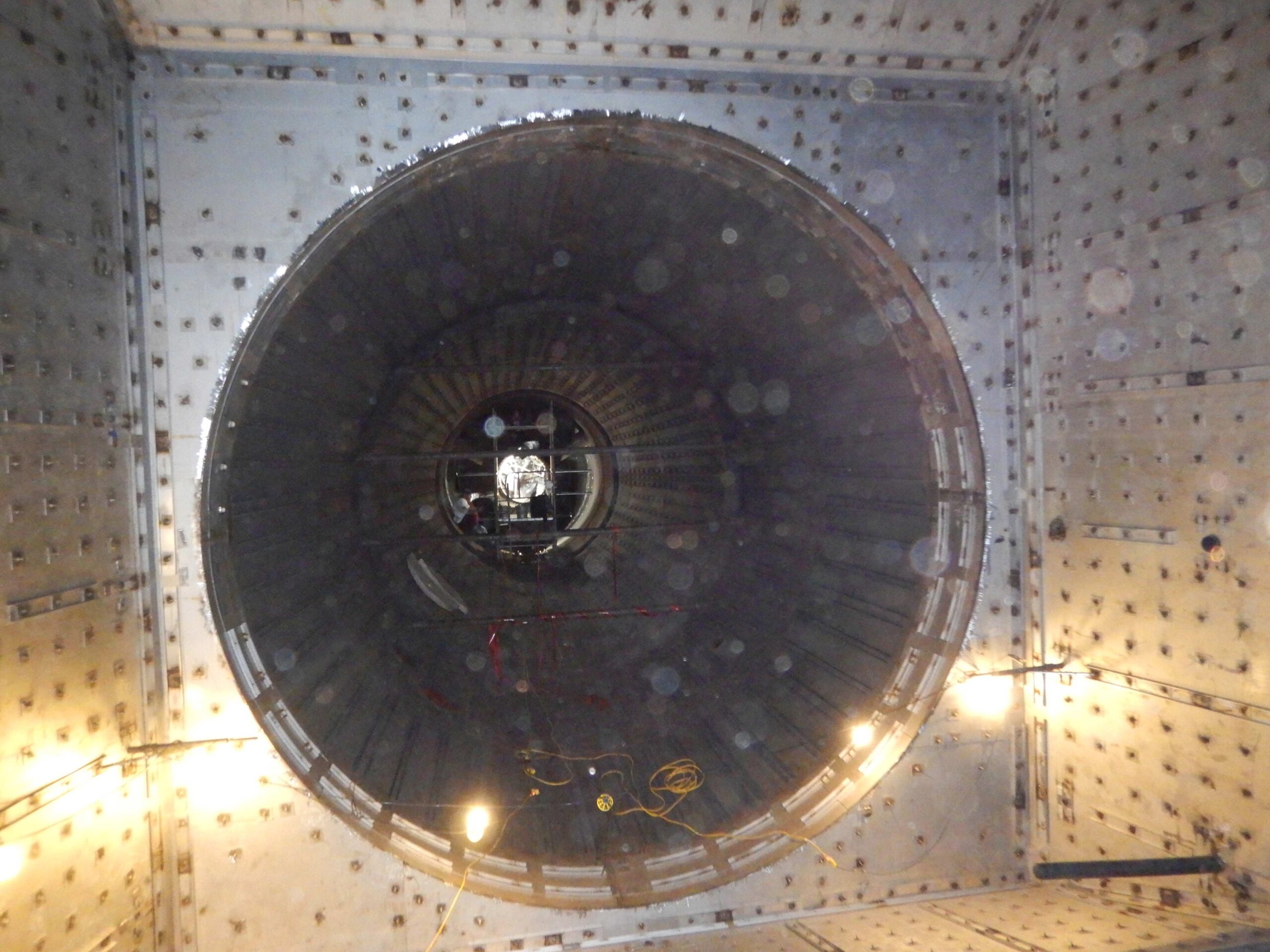

Inlet Duct Liner System

CT Extension Duct

Nooter/Eriksen also provided a redesign and supply of the HP Superheater #1 and HP Superheater #2 interconnecting piping and drain lines in accordance with Nooter/Eriksen’s current design standards. The new piping design provides greater protection against attemperator overspray and subsequent ingress of condensate into the superheater coils due to the addition of drain pots. Nooter/Eriksen redesigned the superheater drain system to accommodate condensate detection through the use of thermocouples and automated drain valves.

Burner Skid

Burner Install

CO Frame Crane Lift

CO Install

- Metal seated ball valves which will reduce the feedwater loss due to valve leakage

- Approximately 60% fewer valves (combined identical pressure drains internal to the HRSG)

- Approximately 60% fewer drain penetrations through the casing

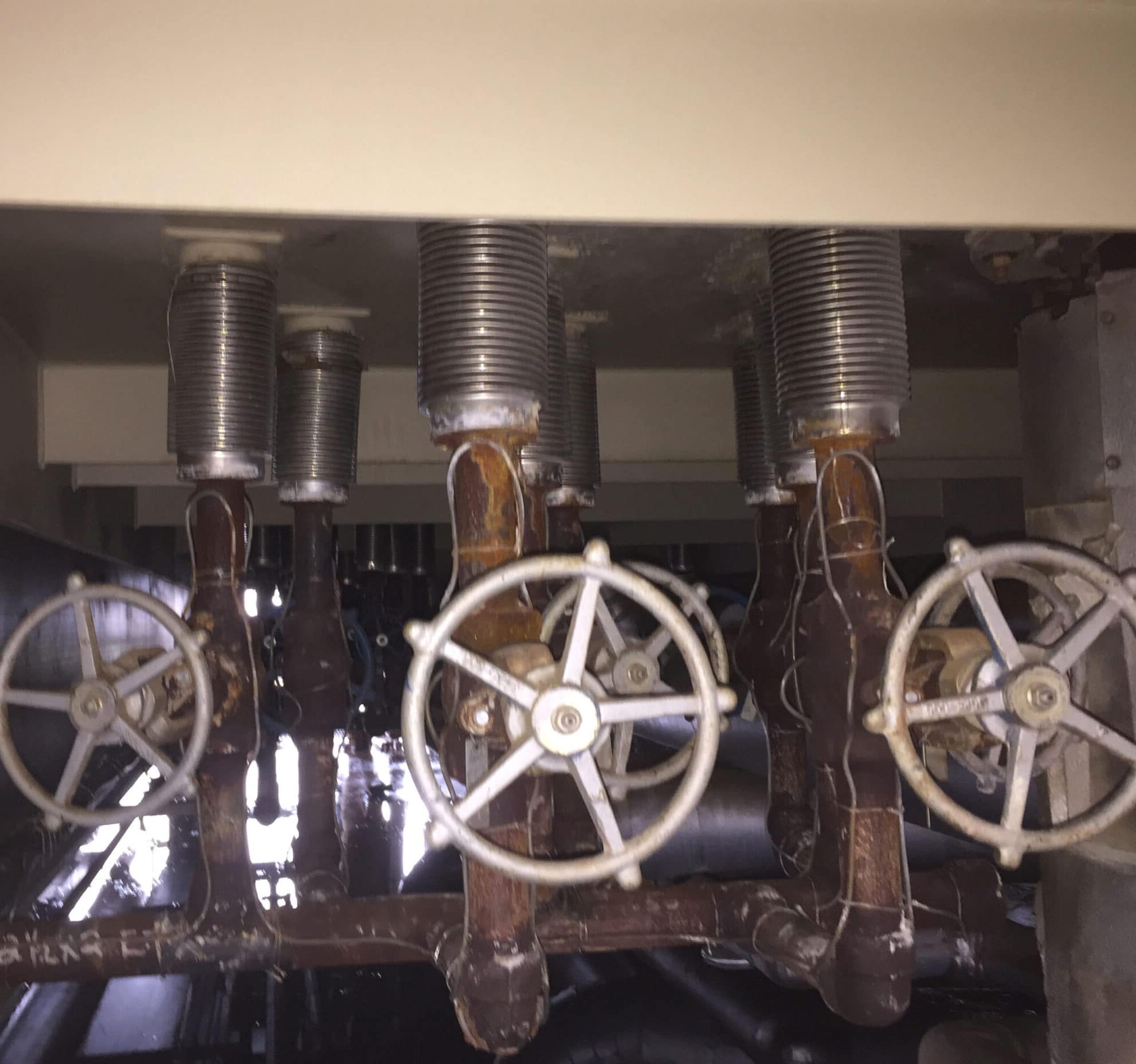

- Internal expansion bellows to eliminate external corrosion of the drain piping

- Easier access to drain valves

The final product created a more efficient layout for plant personnel in addition to a reduction in future maintenance.

Original Configuration:

New Configuration:

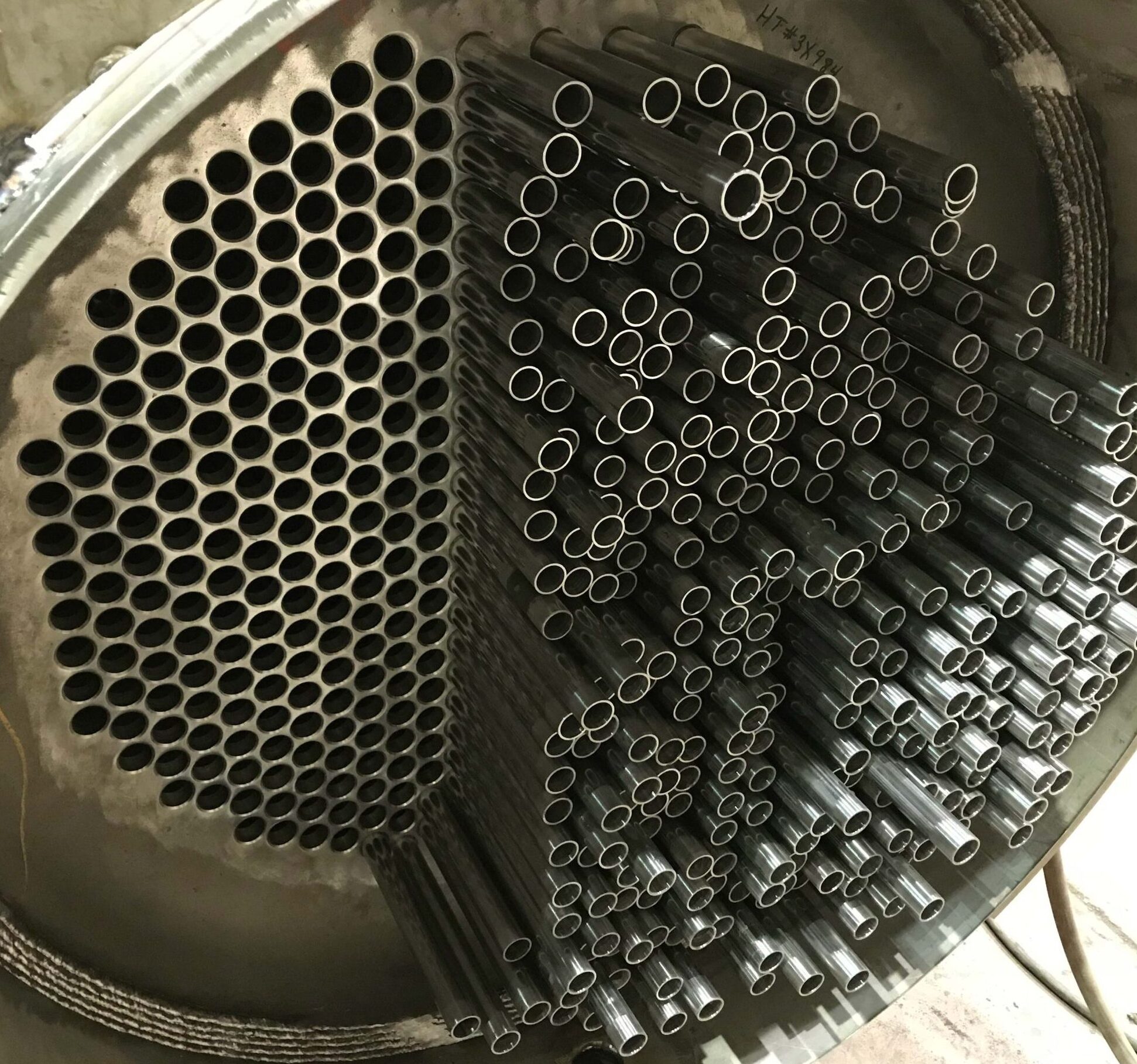

Nooter/Eriksen completed an engineering study along with a new design and supply for the IP Rotor Air Coolers (RAC) for a customer in the Northeastern US. Many factors had contributed to repeated failures in the IP RACs including but not limited to a competitor’s original design, water chemistry issues as a result of material selection (chloride induced stress corrosion cracking), operation (frequency of cycling and spin cooling), improper restraint of saddle supports, and piping load design discrepancies.

The redesign and supply for one HRSG was successfully completed in 2017 by Nooter/Eriksen. The RAC performed well. In 2018 Nooter/Eriksen completed a similar new design and supply of the IP Rotor Air Cooler (RAC) for the second HRSG as well.

RAC Fabrication

RAC Fabrication

Nooter Eriksen has completed multiple Stack Damper installs over the years. We offer a turnkey service by providing the engineering, drafting, materials and labor. This scope includes the install of the damper, maintenance platform and external stack insulation.

Reducing Start up time can be a critical cost saving measure. Maintaining a warmer temperature inside the HRSG can greatly help achieve this reduction. An excellent way of achieving this is by utilizing a damper in the exhaust stack in combination with insulating below the damper.

While the unit is offline and the damper is closed, airflow is minimized through the CT and HRSG, reducing heat loss throughout the unit and maintaining the ability to perform a hot/warm start for an increased time period.